Read the original article here.

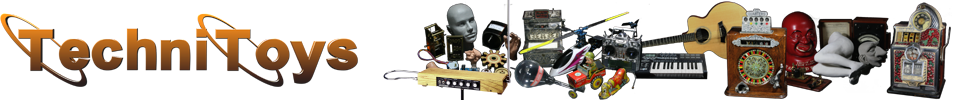

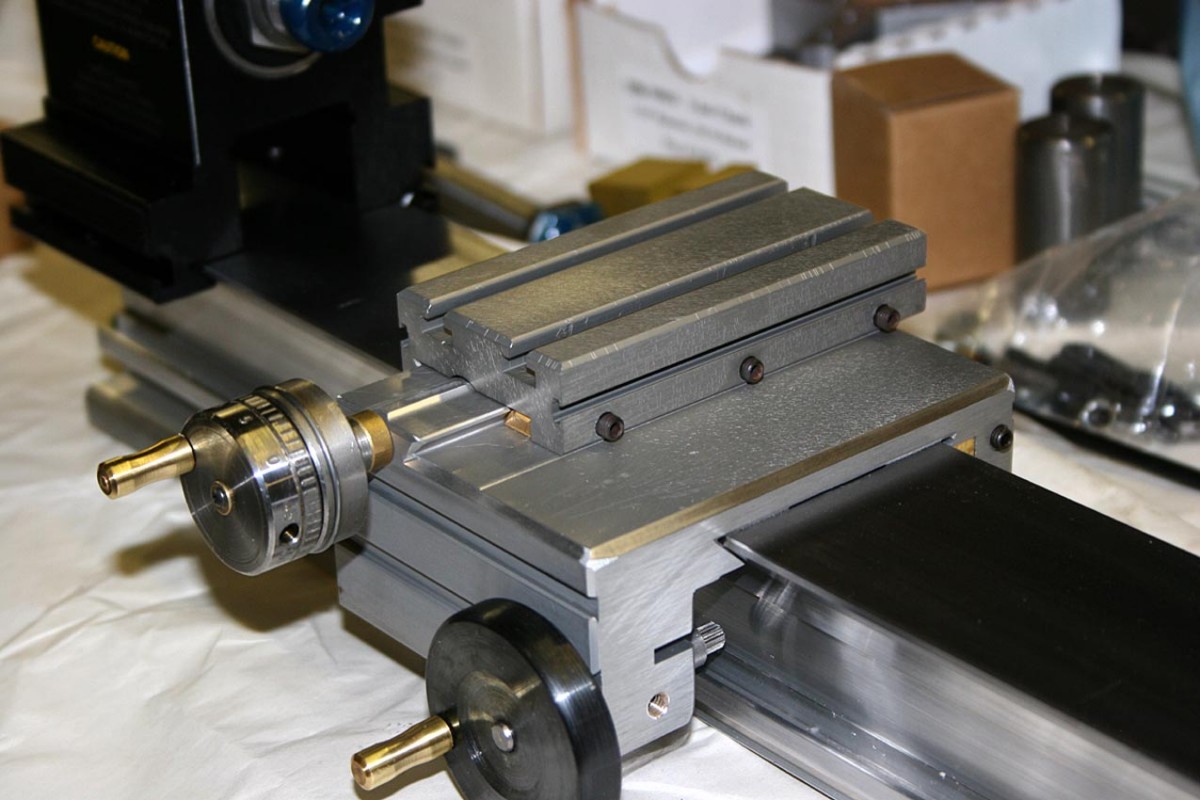

- Taig Micro Lathe II With Modifications

- Customized Taig Micro Lathe II for Smaller High Speed Work

- The Microscope Aids Fine Work and Lets You See How Bad You Are at Bit Sharpening

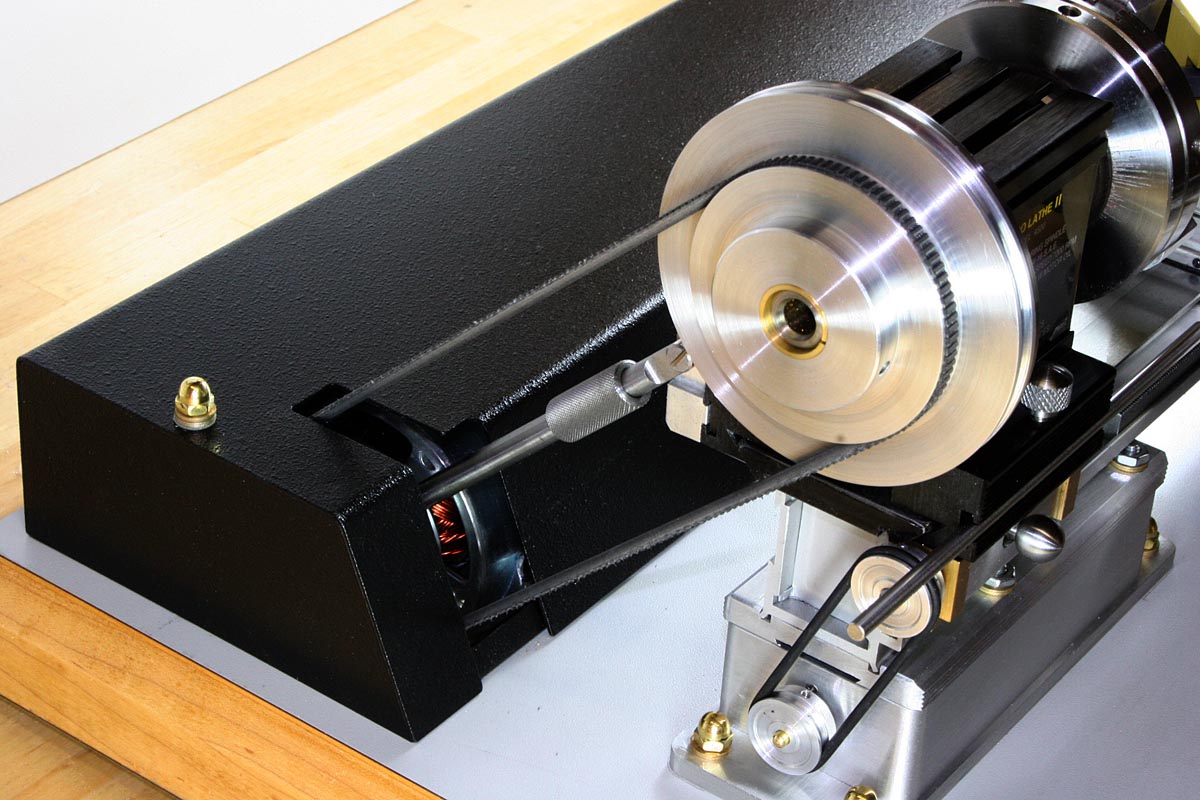

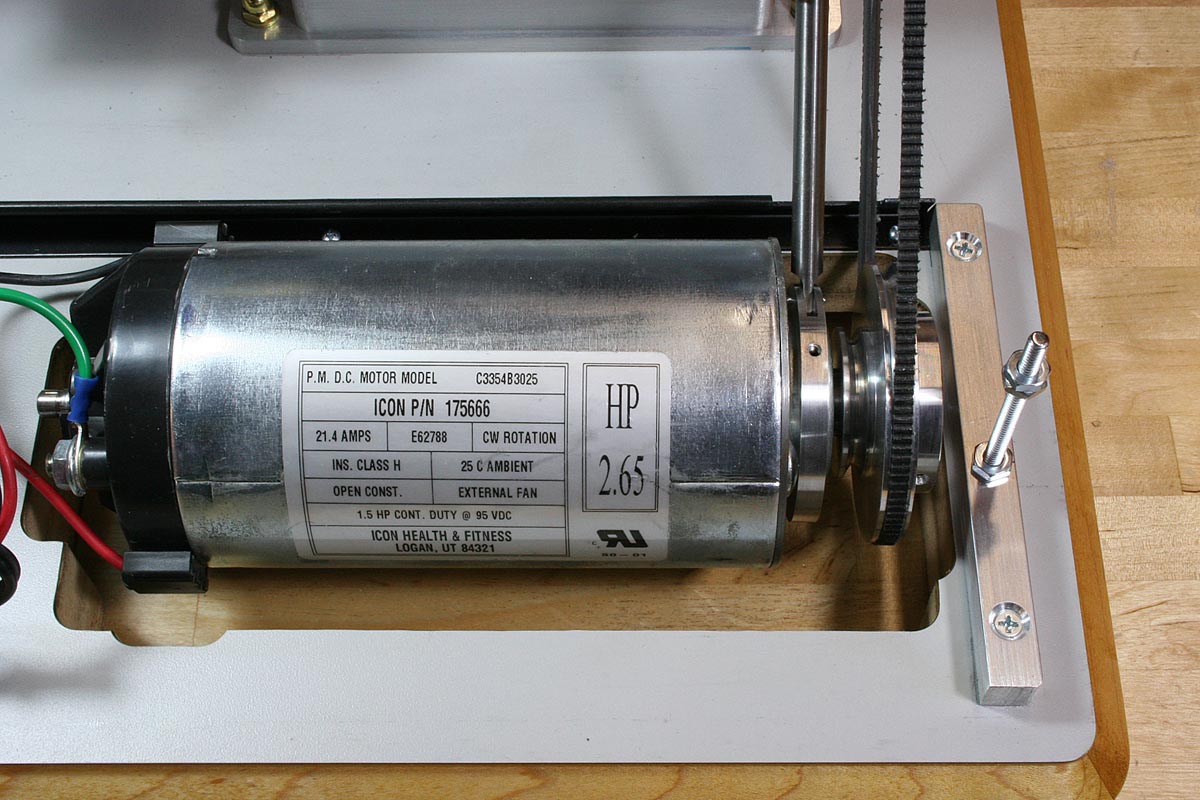

- A Powerful DC Motor & Controller is Hiding Under that Cover

- Chucks and Accessories. Good Quality and Inexpensive. Buy Plenty.

- Etched Aluminum Control Panel

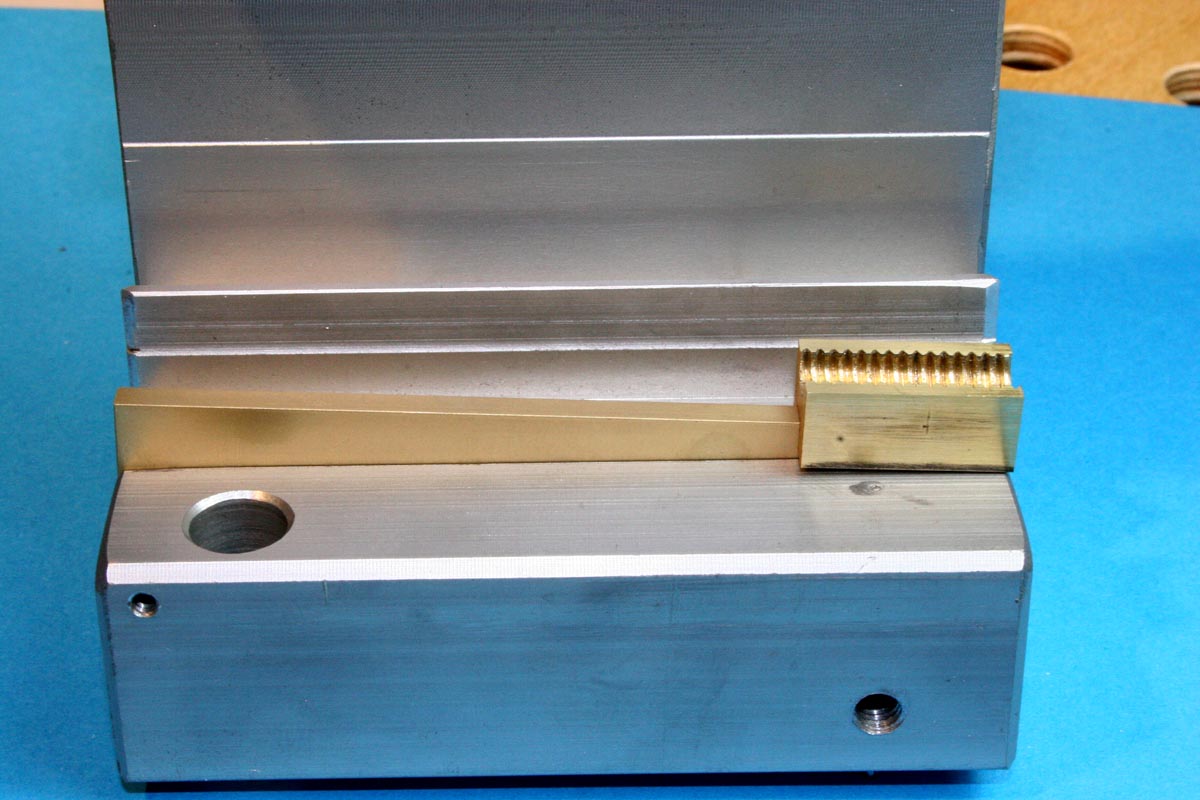

- Jig for Clamping Carriage in Milling Machine Vise

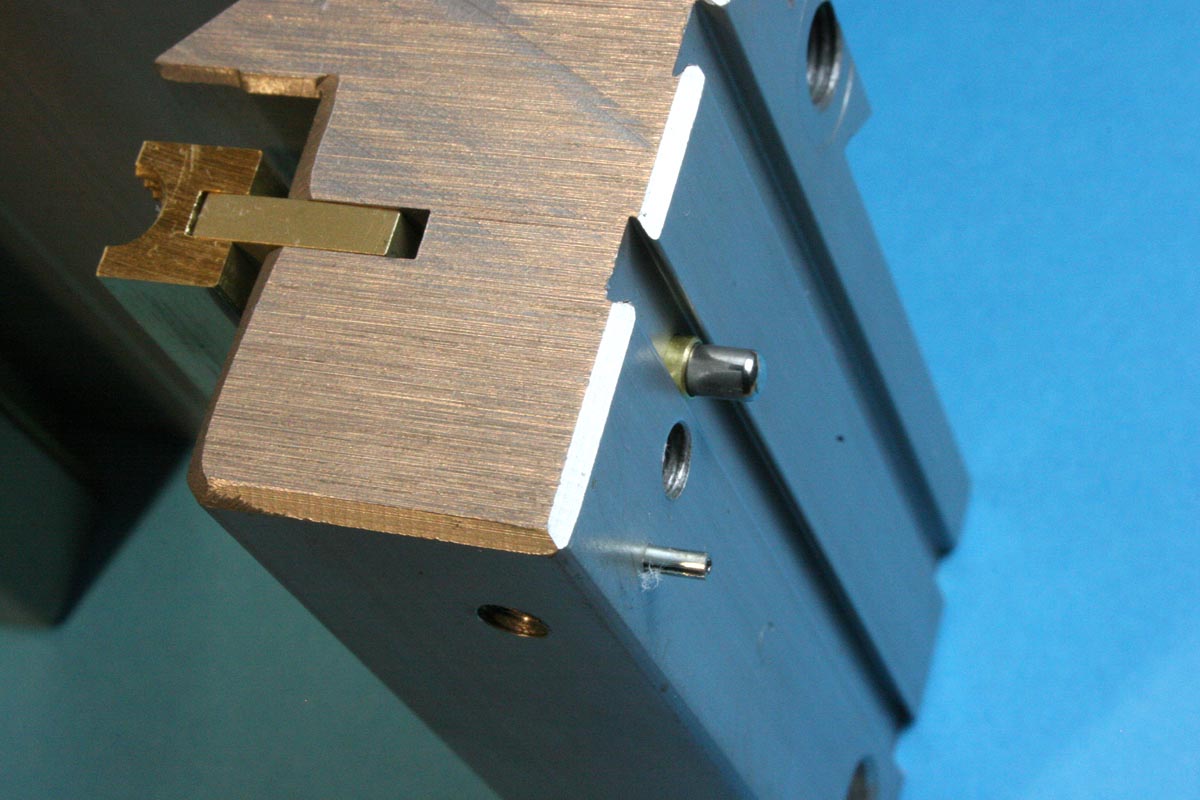

- Edges of Carriage Cleaned Up a Bit

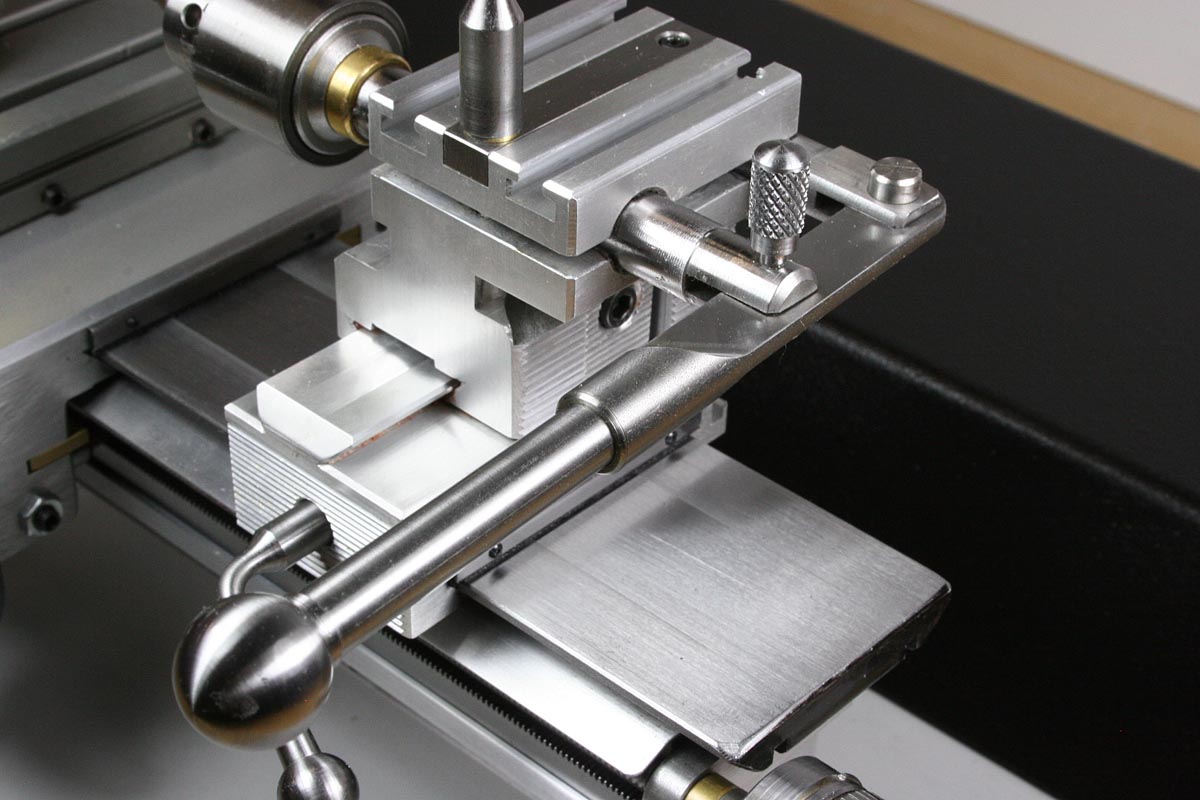

- New Tailstock Lever

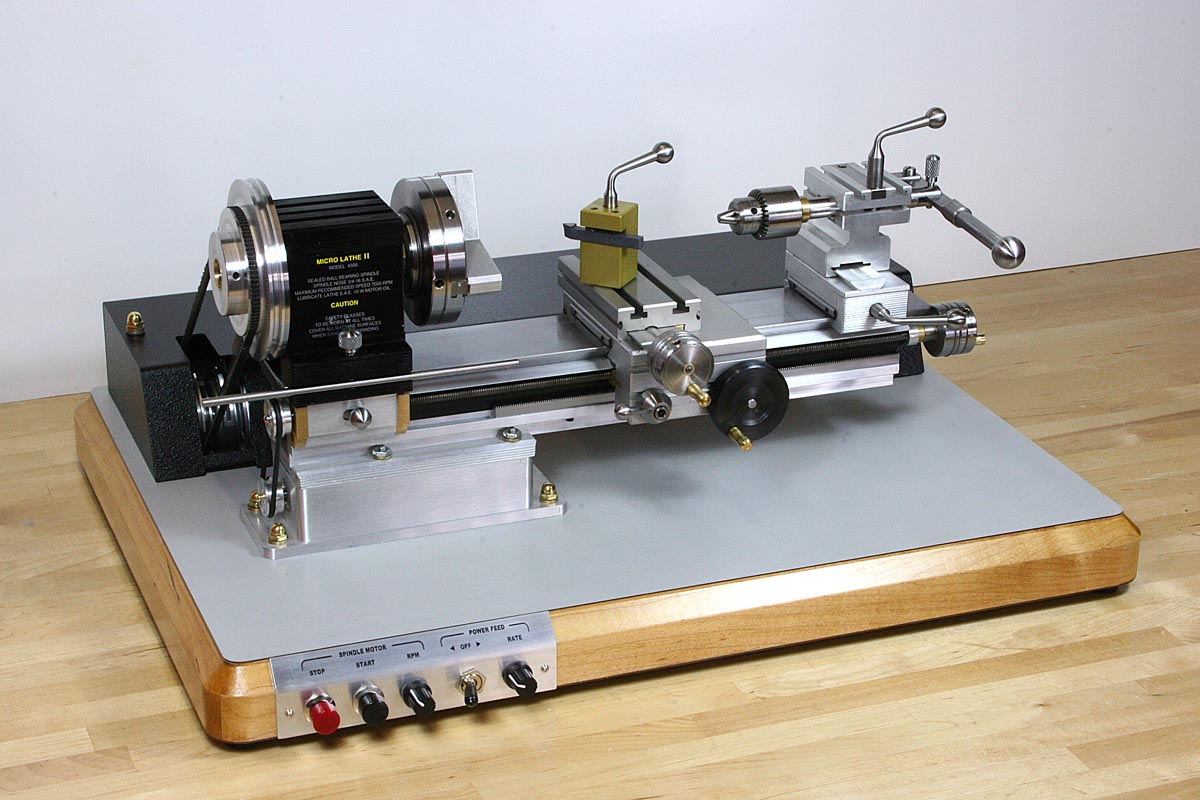

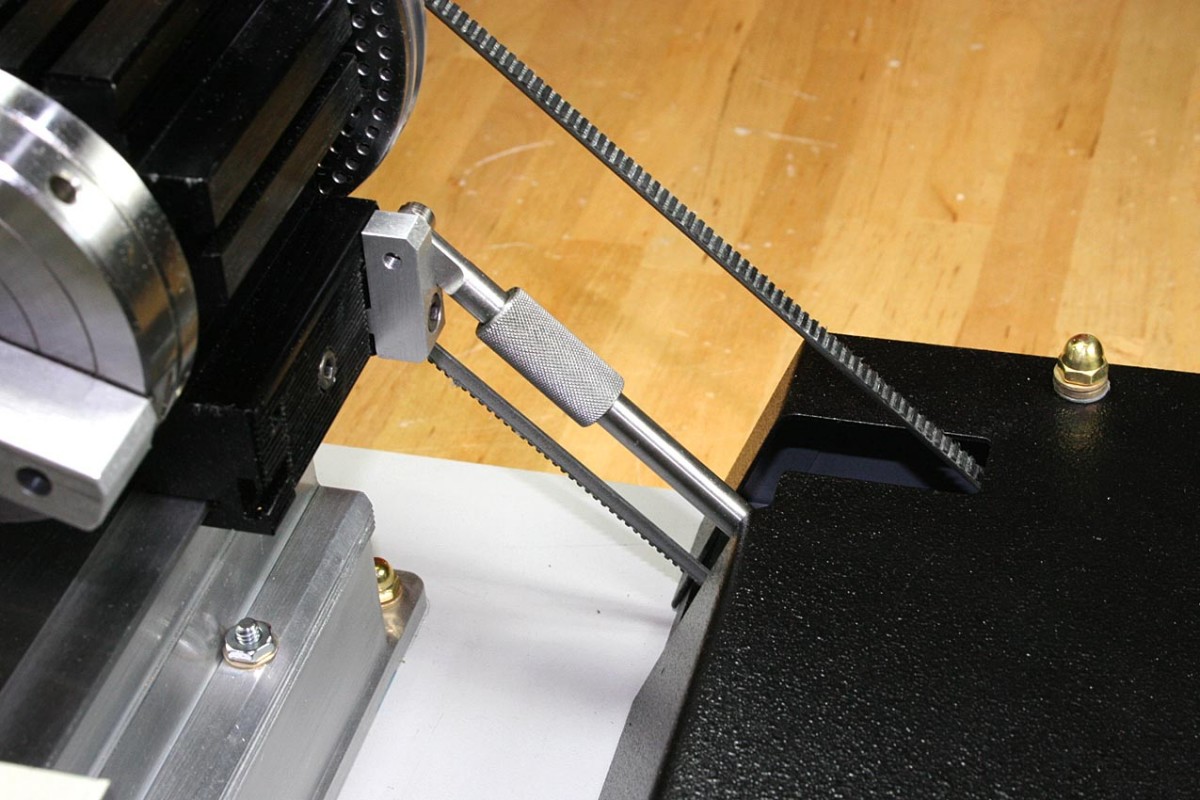

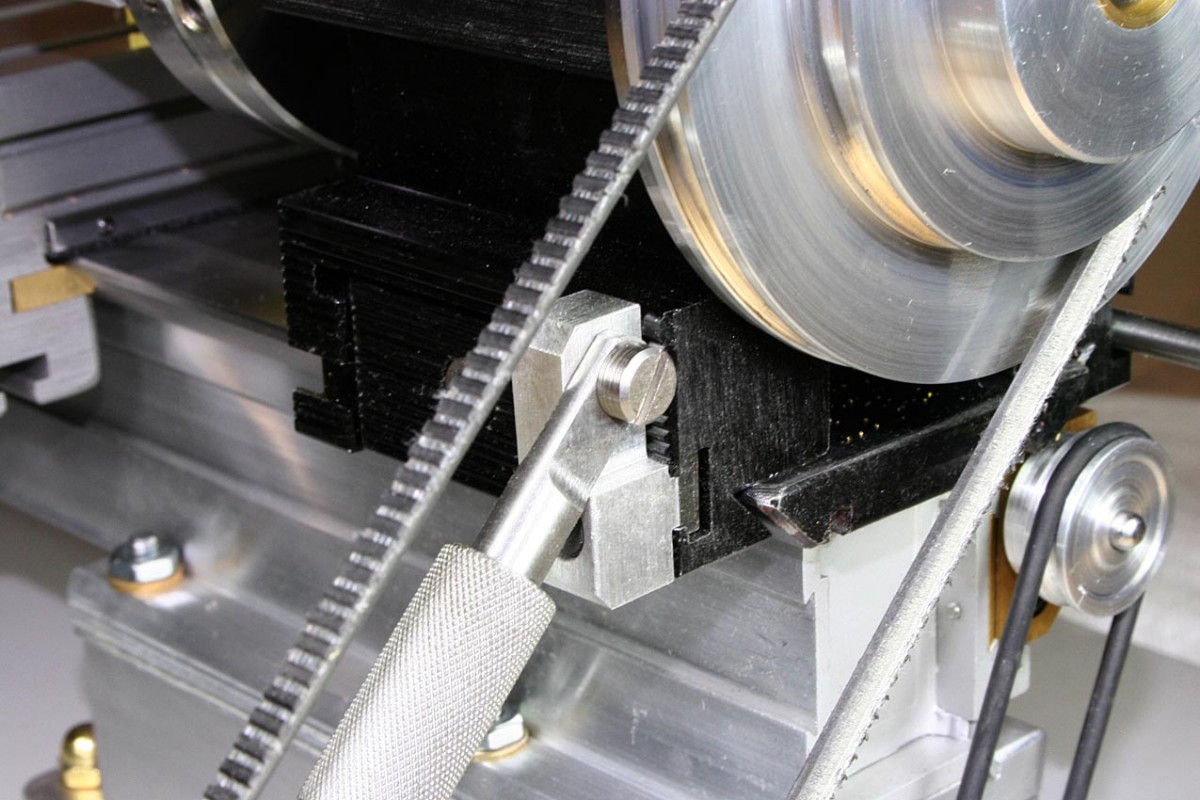

- A Nearly Ideal Location For a Belt Tensioner

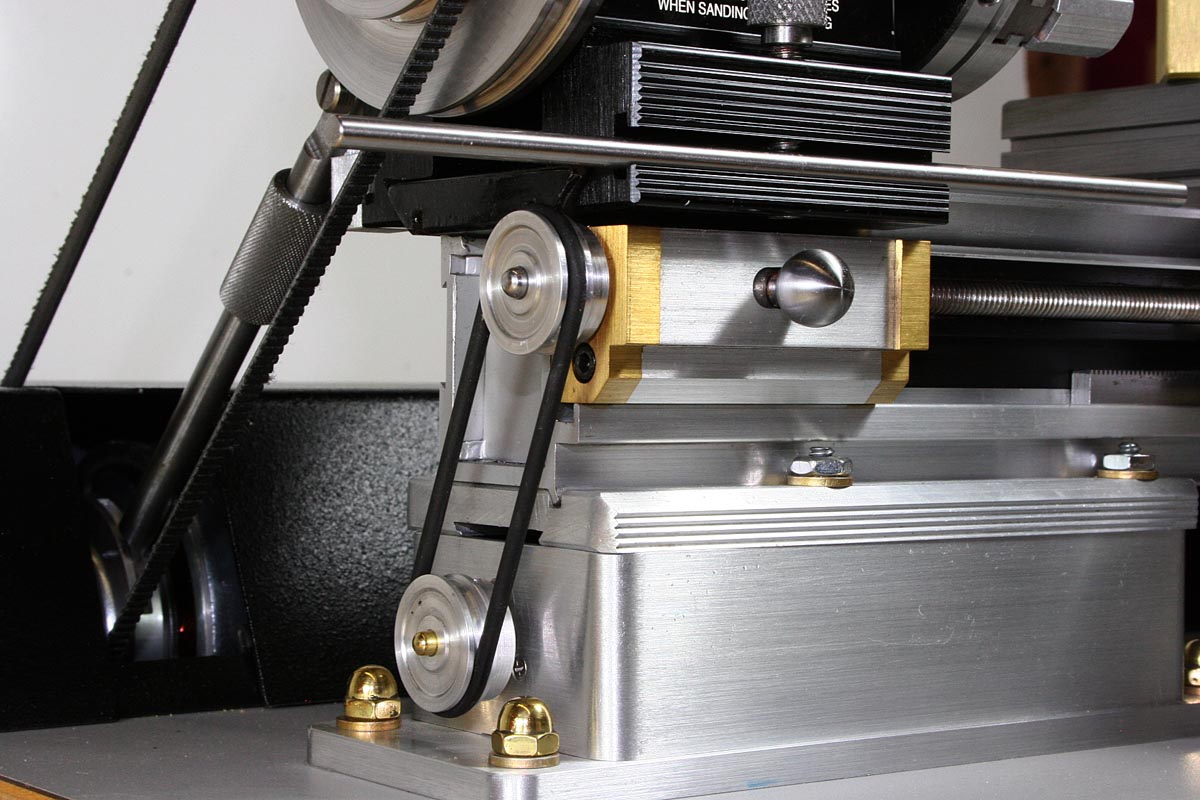

- The Belt Tensioner in Context

- The Belt Tensioner – Headstock End

- Belt Tensioner – Motor End

- Headstock End of the Tensioner

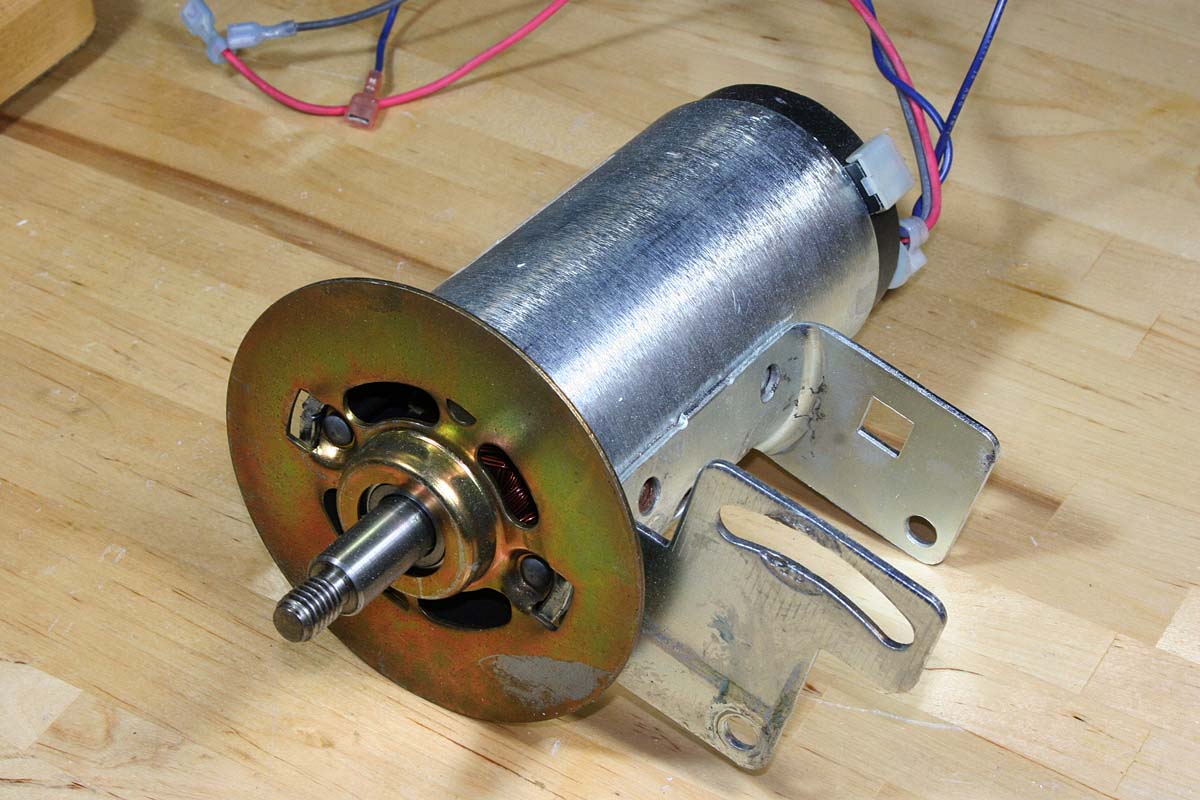

- Treadmill Motor Similar to the One Used Here

- Treadmill Motor Partially Hidden in Base Cavity

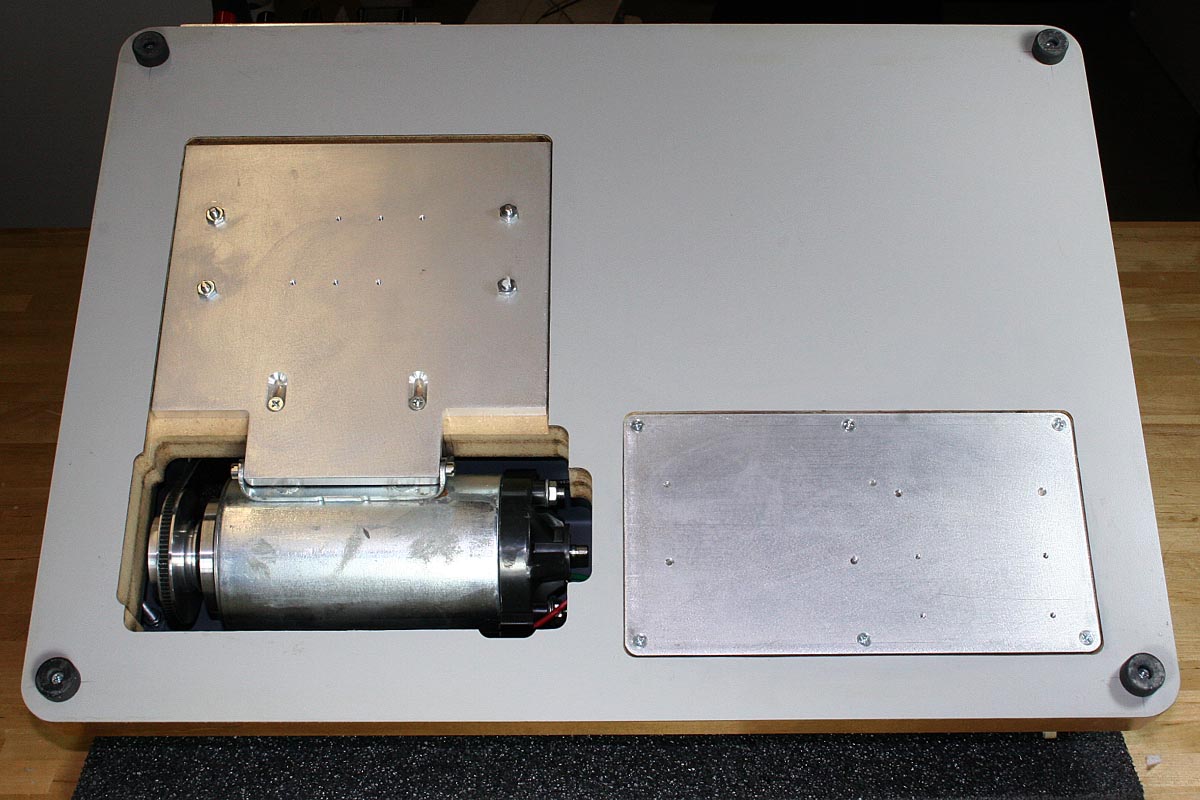

- Underside of Lathe Base

- Detail of Cut-Down Motor Mount

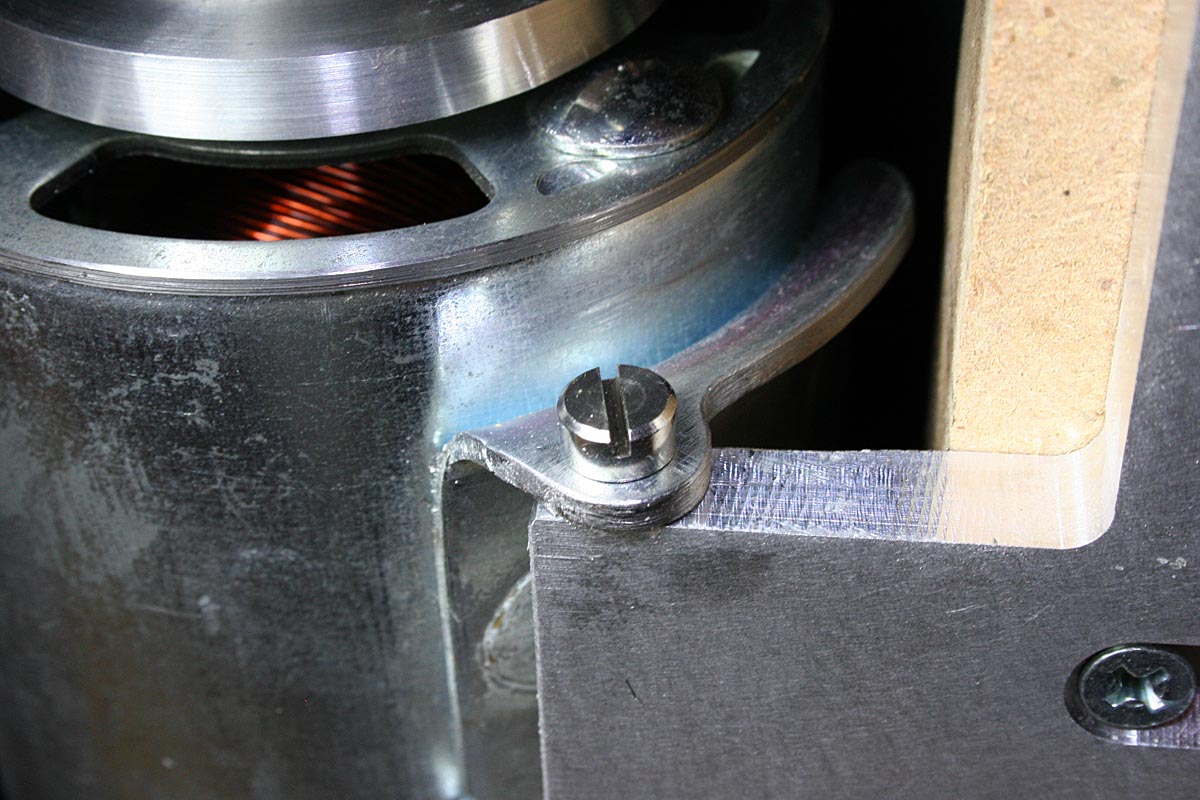

- Closeup of Pivot Fork

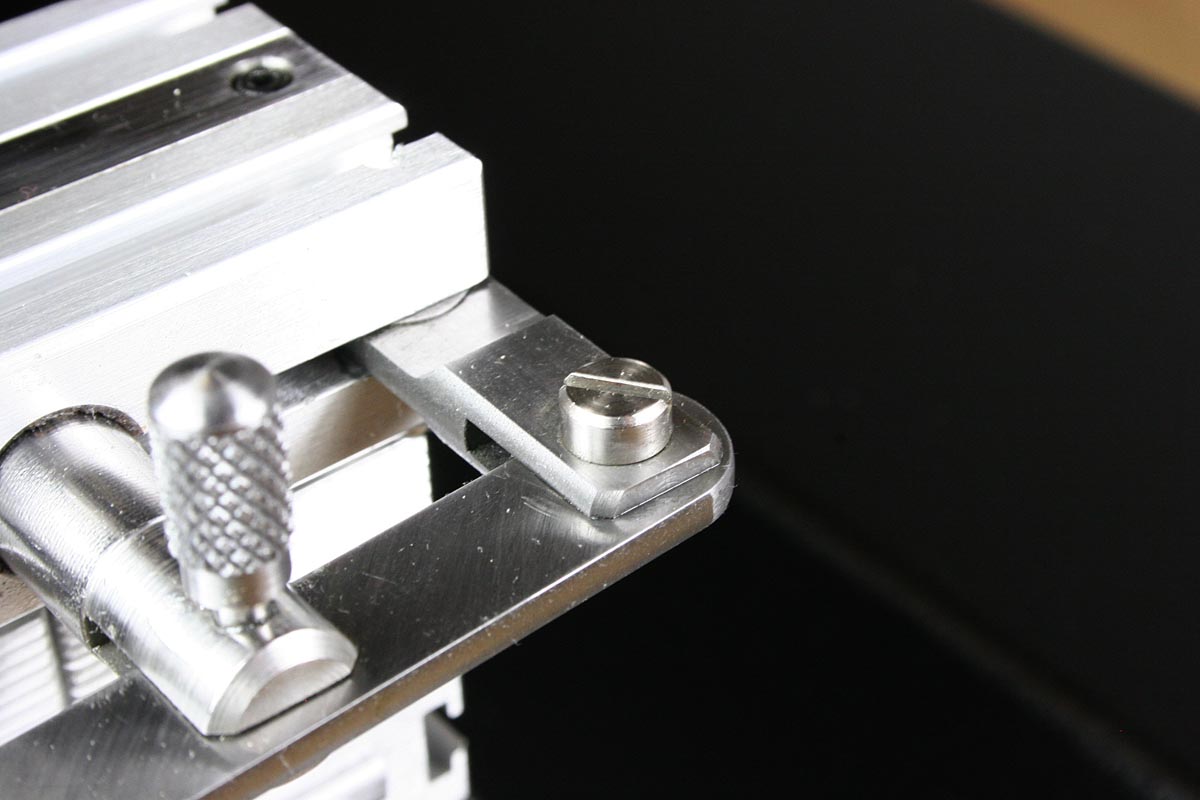

- Clutch Mechanism For Engaging Power Feed

- Closeup of Plastic Lead Screw Back Support

- MDF Clamp for the Acetal Lead Screw Support. The Clamp Never Left the Vise.

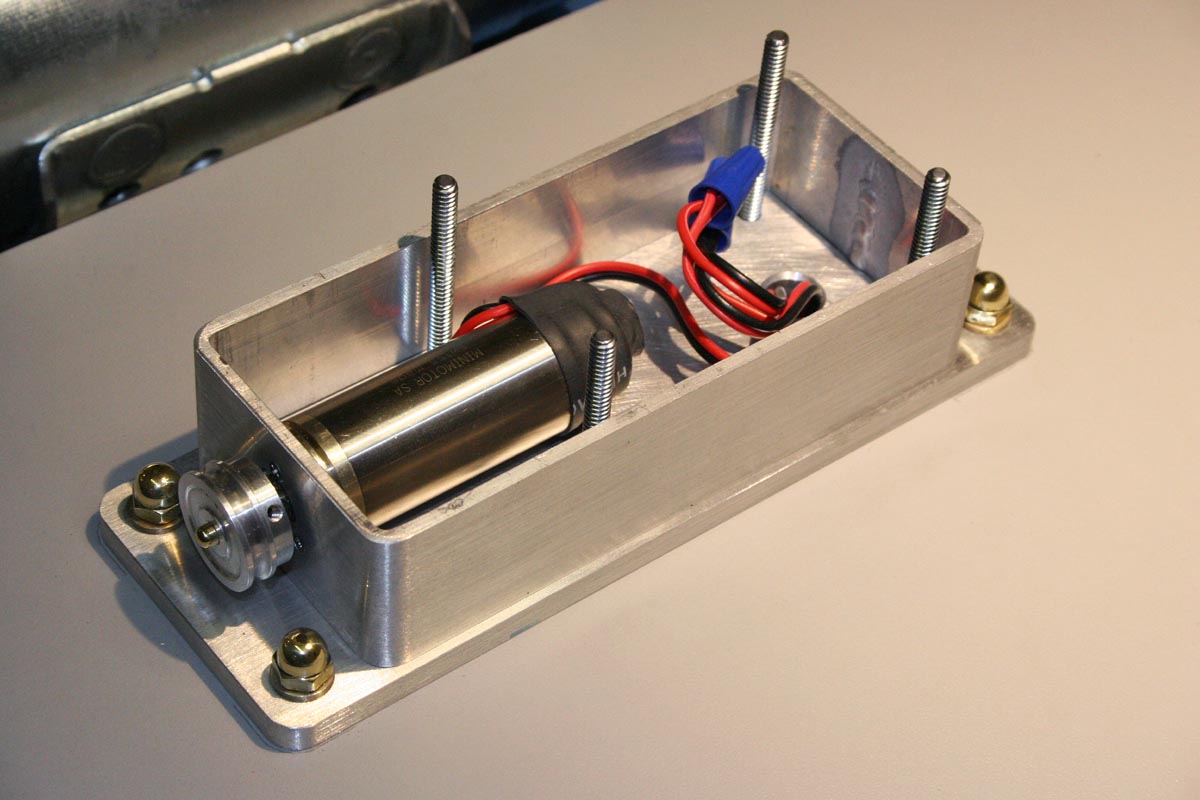

- A Variable Speed Gearmotor Hidden in the Riser Drives the Lead Screw

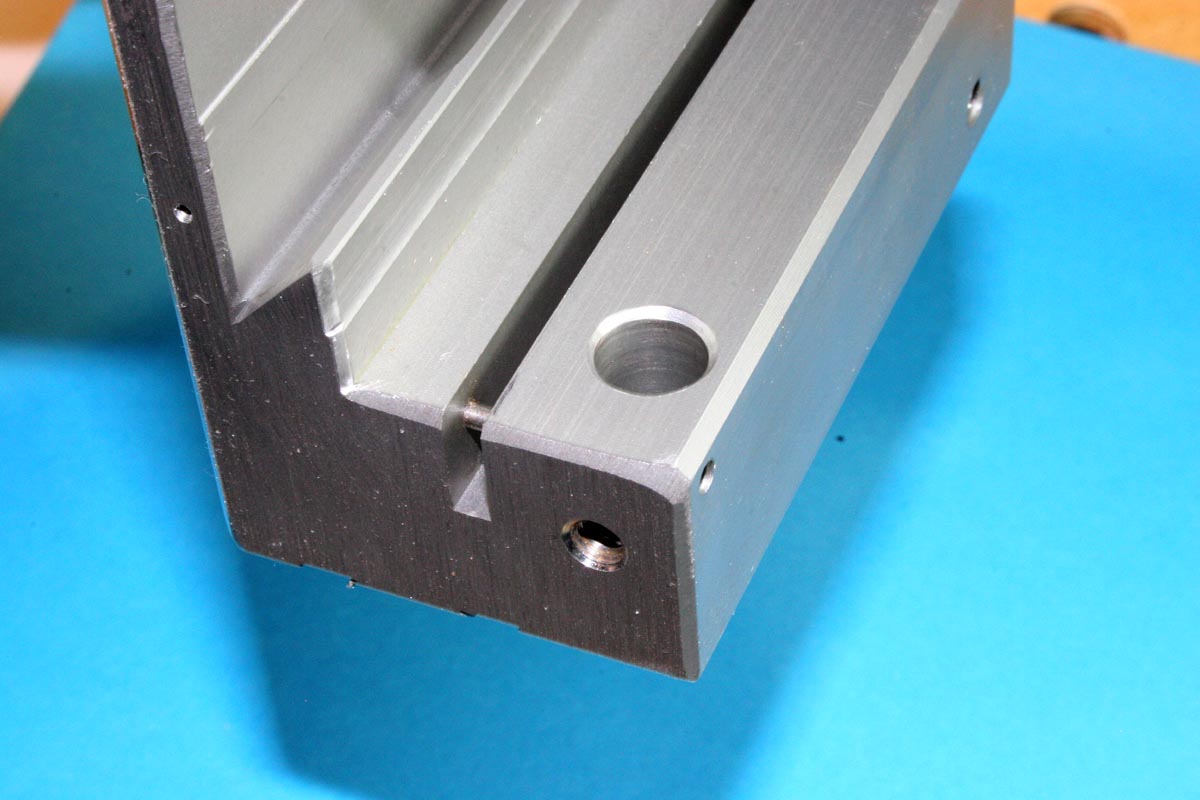

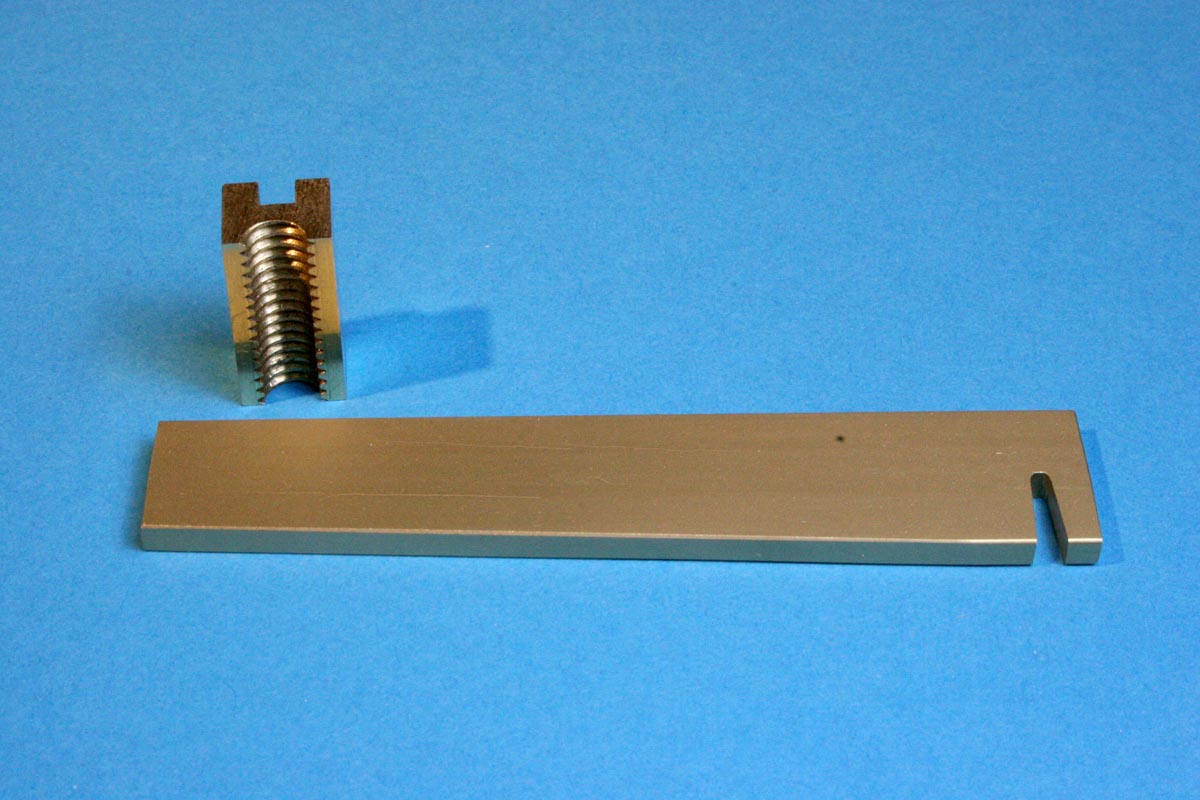

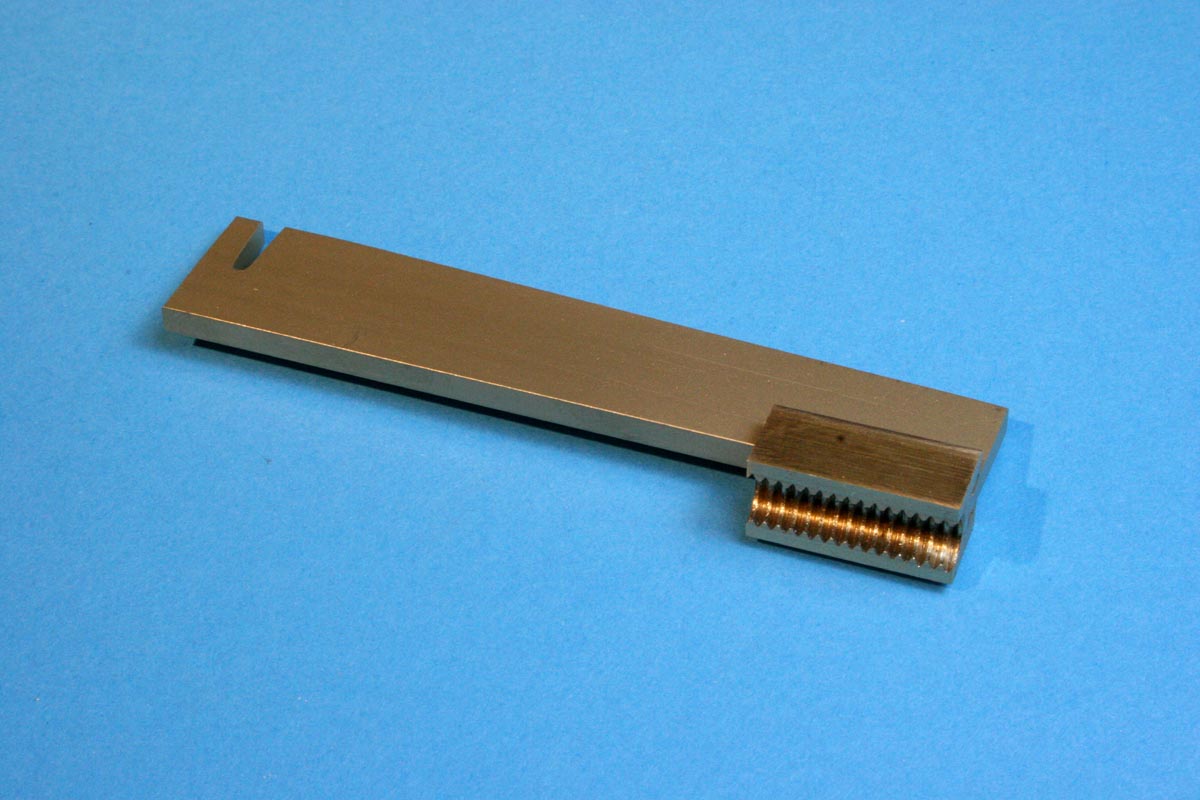

- Components of the Lead Screw Clutch

- Gear Motor for Power Feed

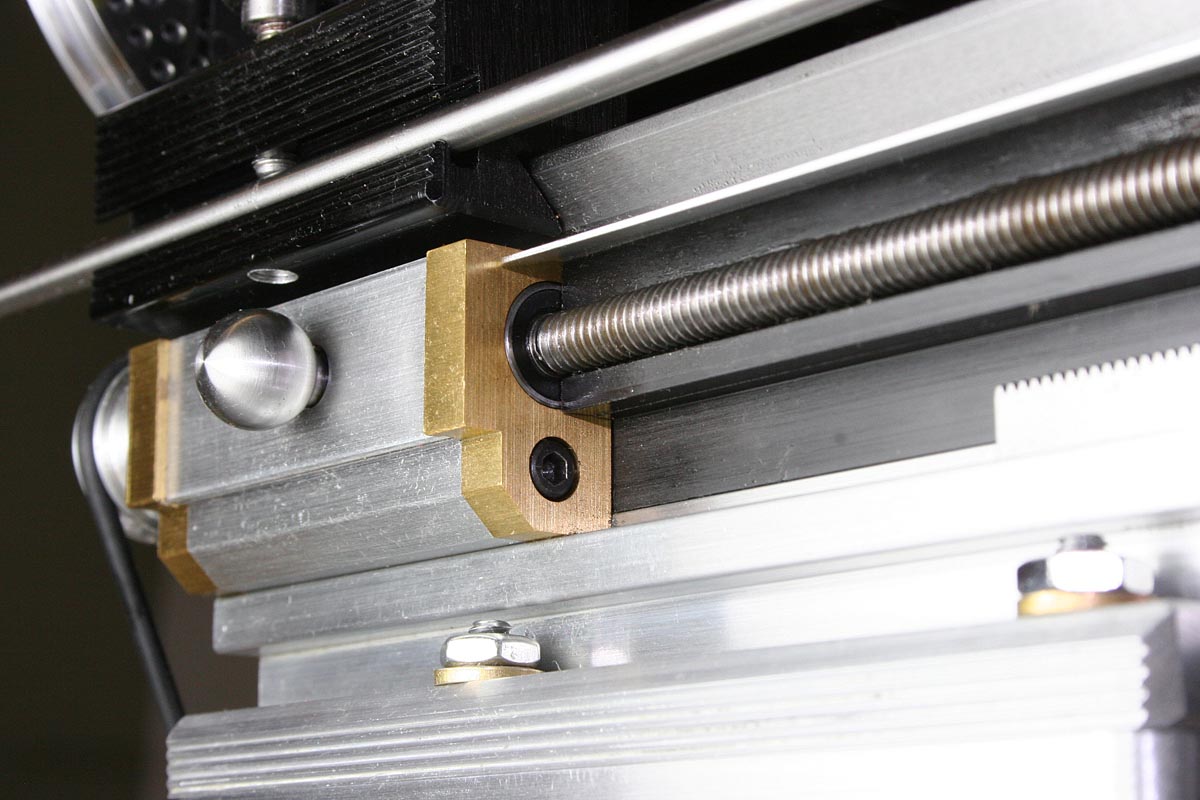

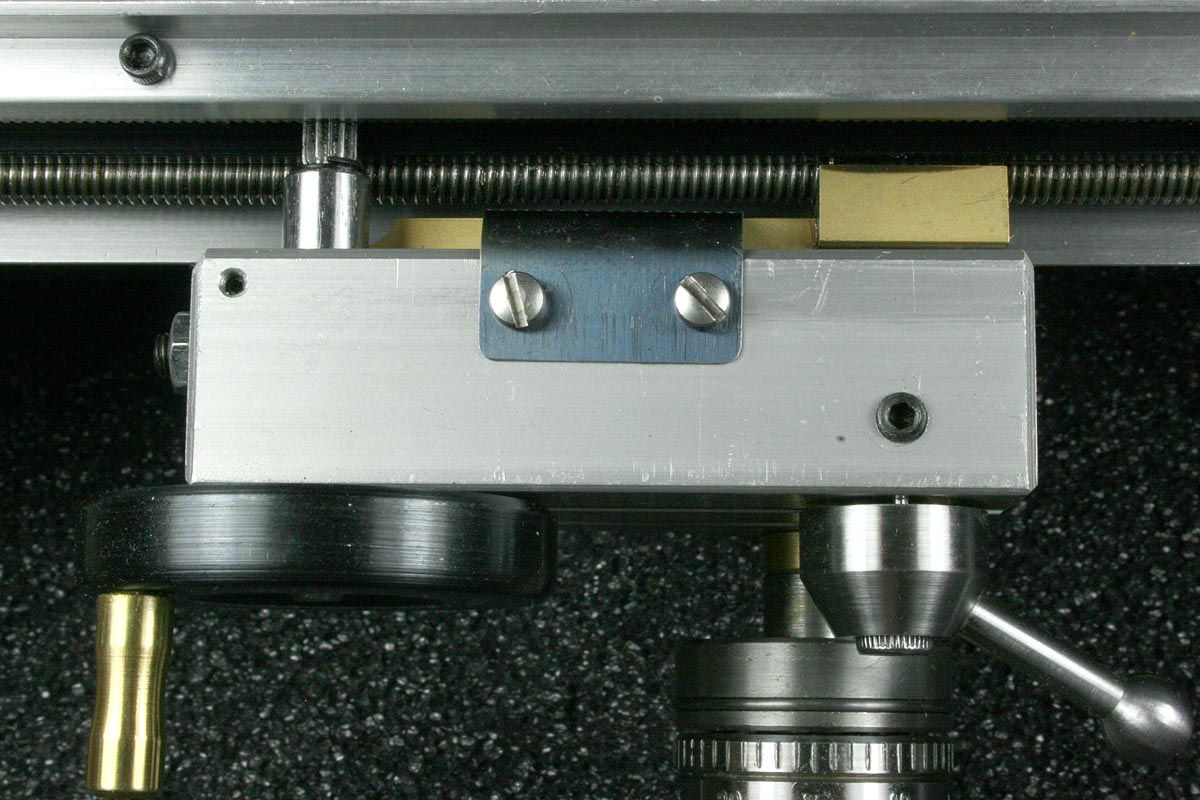

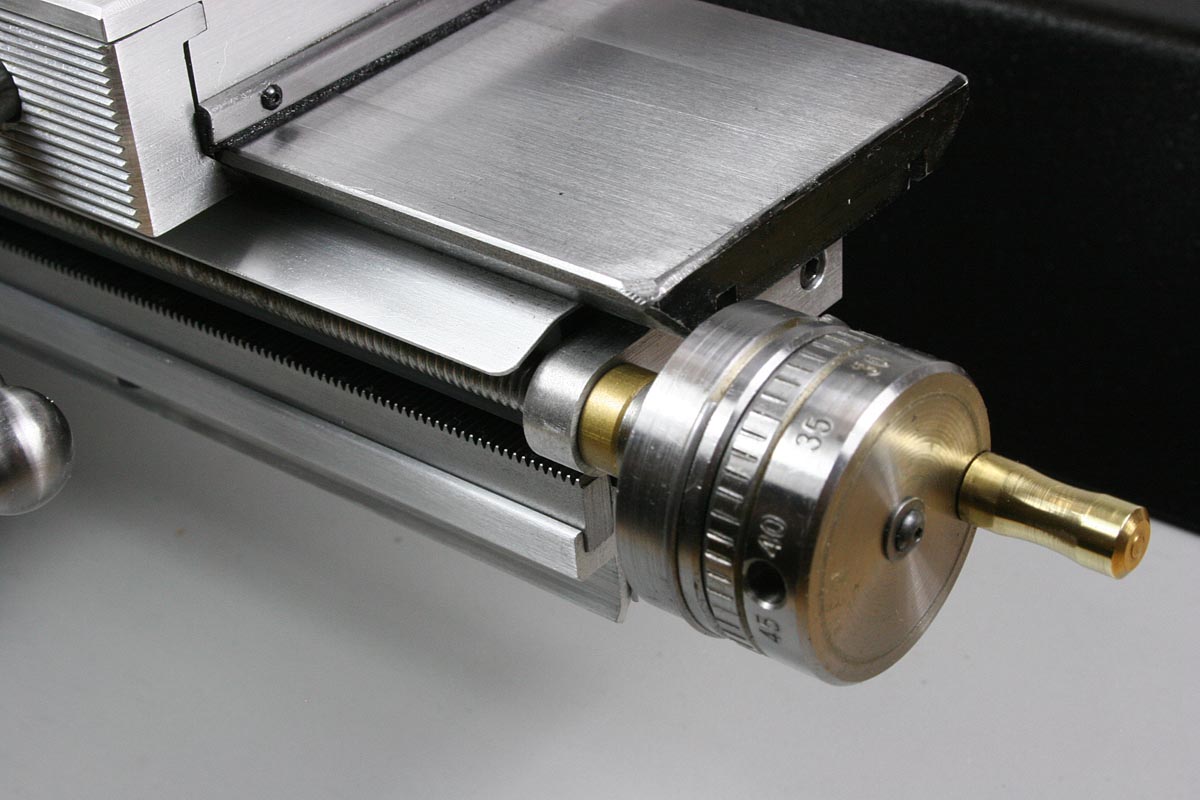

- Feed Knob Engages Brass Nut with Lead Screw

- Bottom of Carriage Apron – Feed Engaged

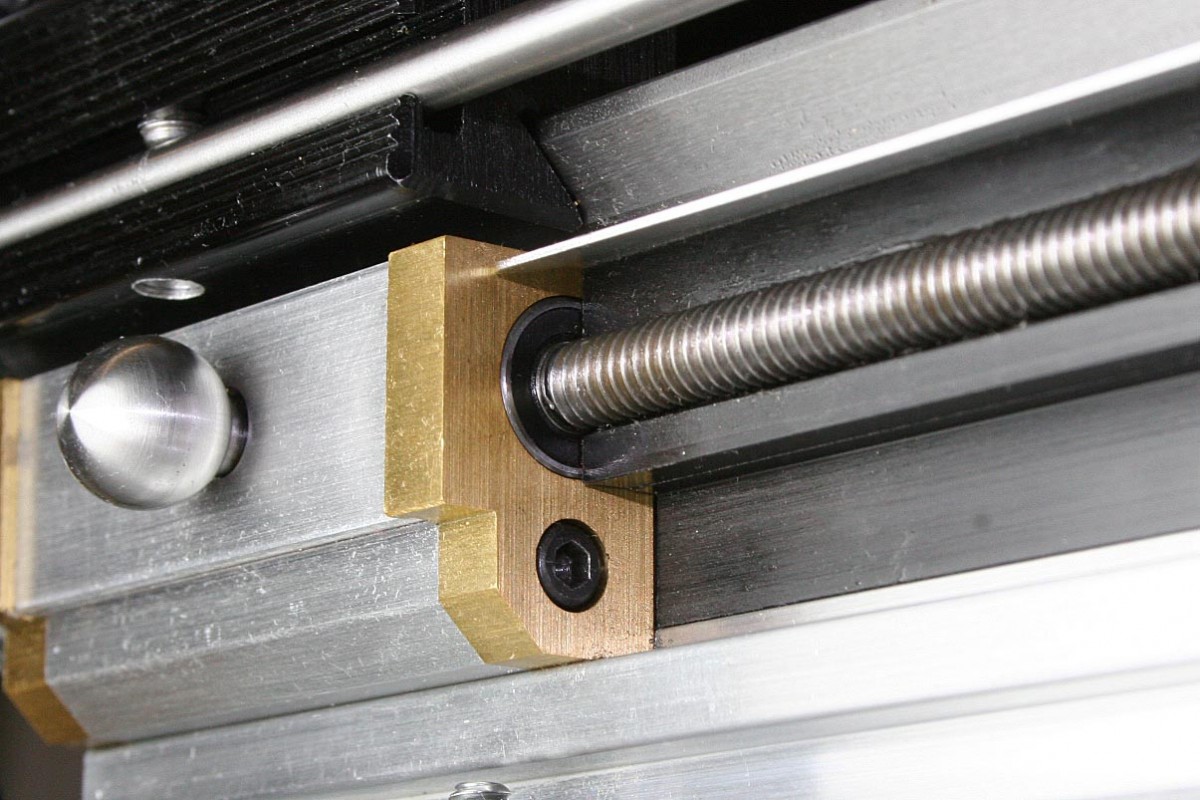

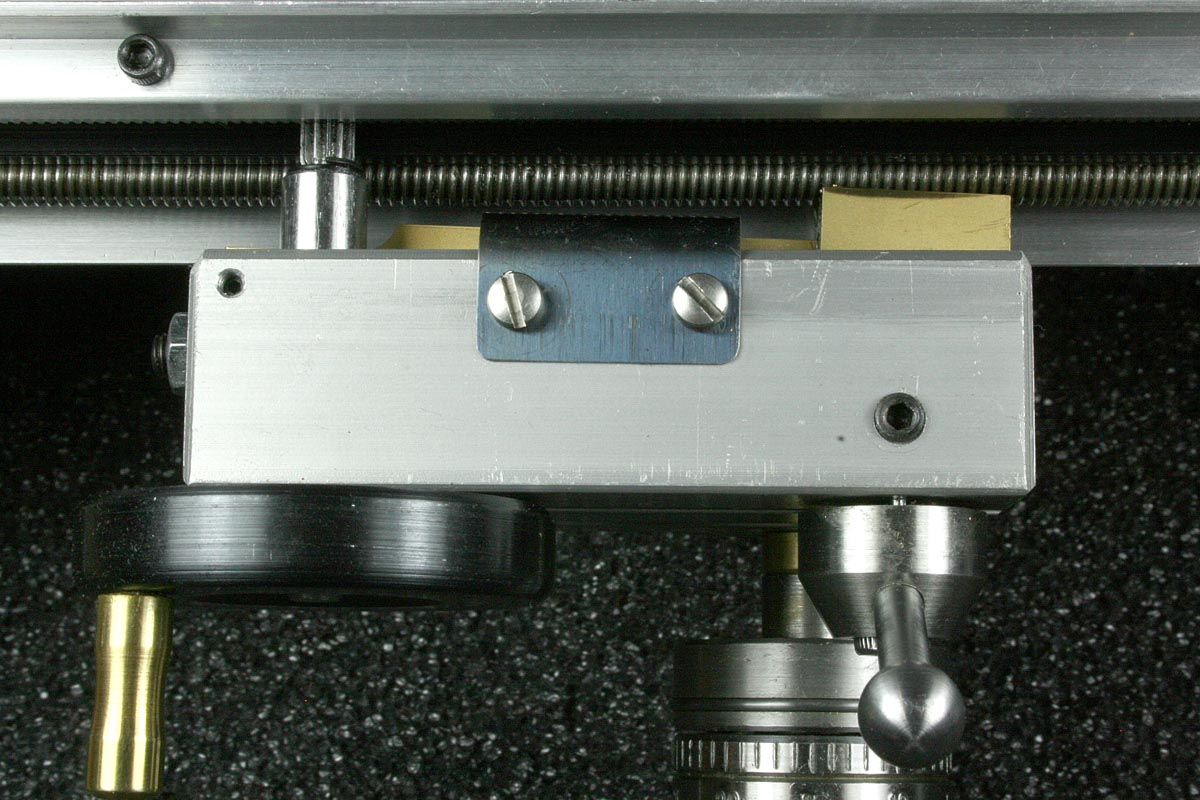

- Feed Disengaged – Not Much Movement Needed

- Half-Nut Engagement Lever in Front Apron – Fully Disengaged Position.

- The Large Pin Pushes the Brass Nut Into the Lead Screw

- Rear View of Cross Slide Apron – Note the Slot. How Convenient!

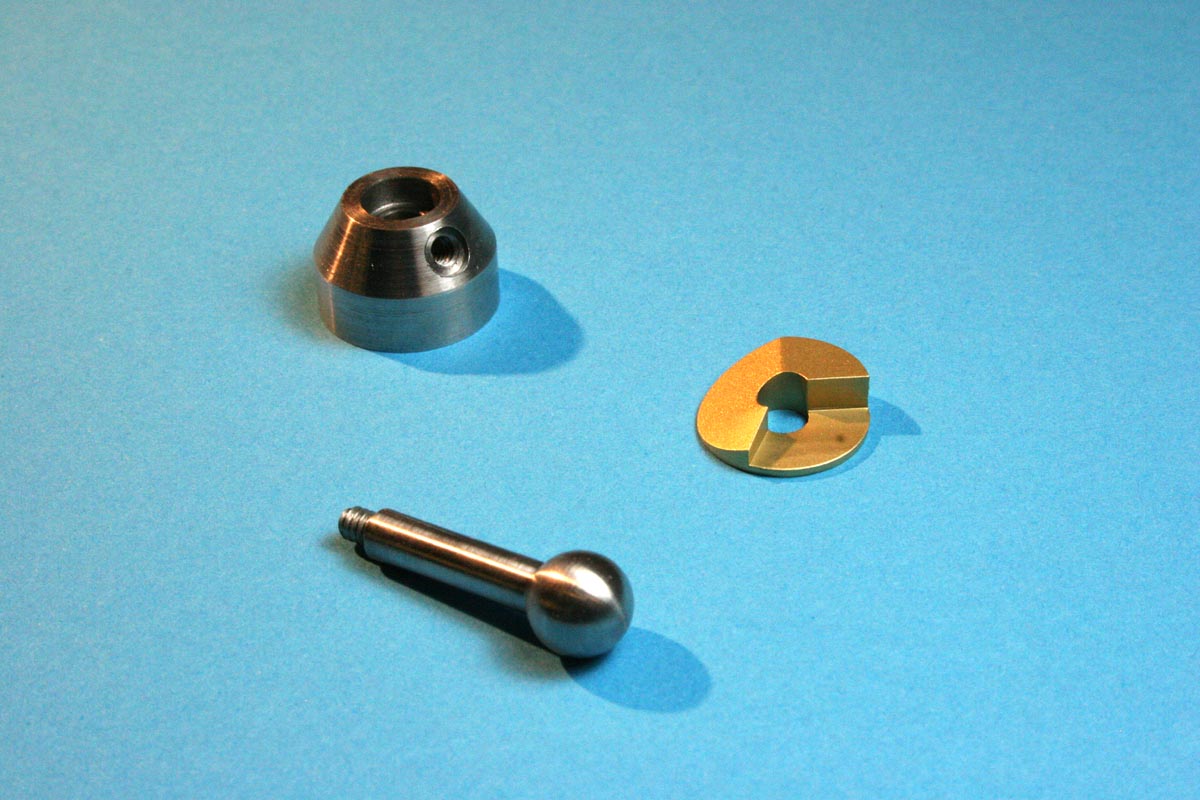

- Parts for Half-Nut Engagement Lever

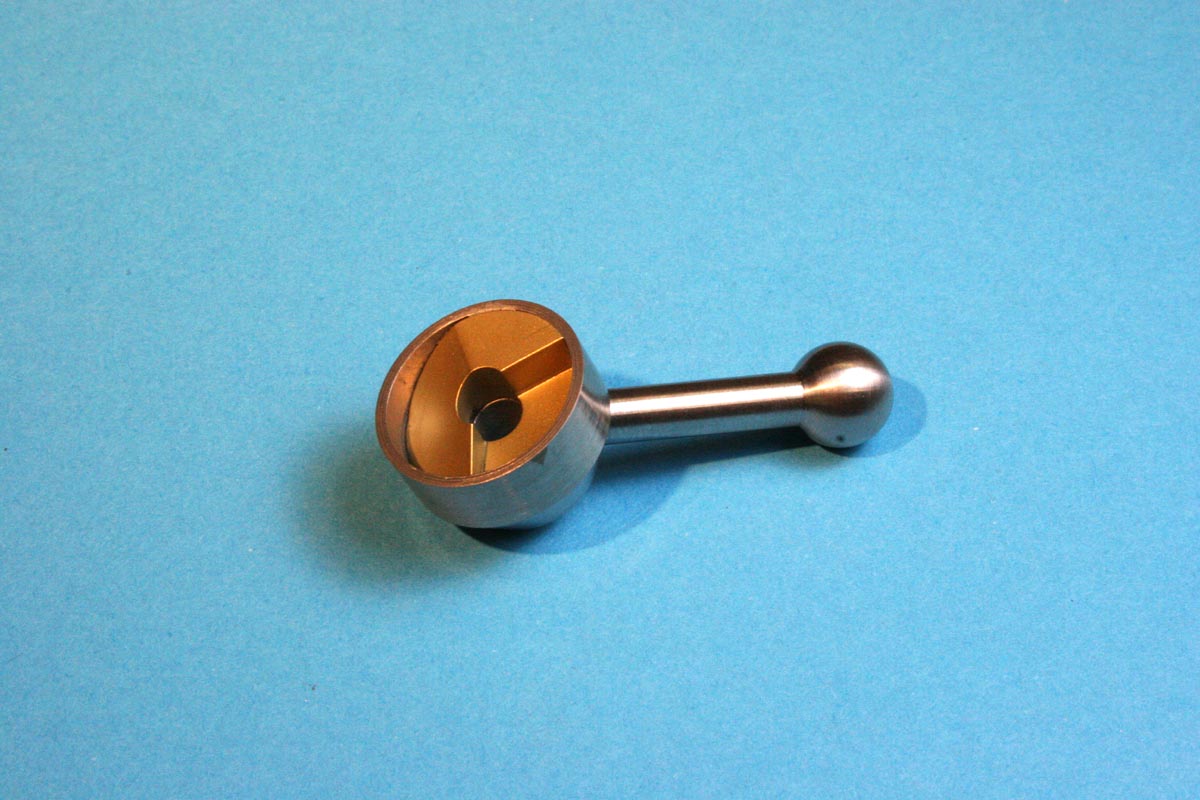

- Parts for Half-Nut Engagement Lever Assembled

- Feed Knob Components

- Feed Knob Front View

- Feed Knob Components Soldered Together

- A Modified Cross Slide Dial Allows Manual Feed When Power Drive is Disengaged

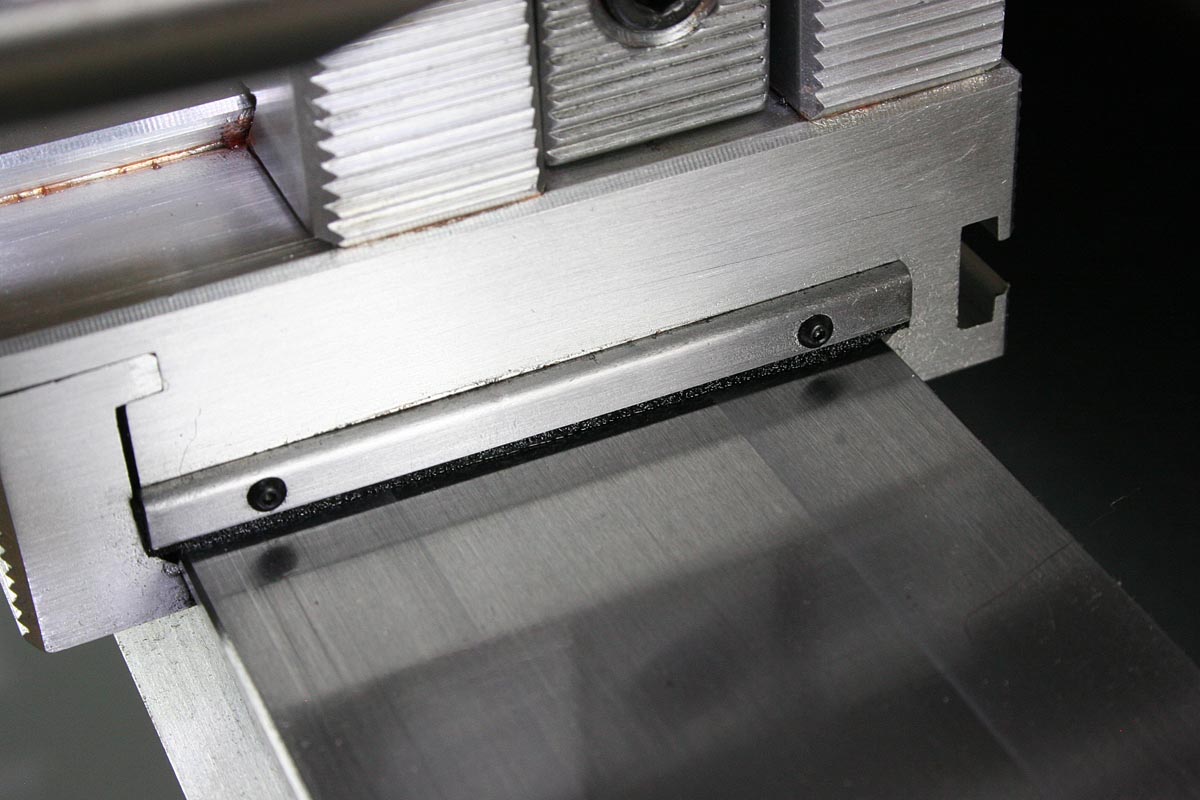

- Bed Wiper on Tailstock .

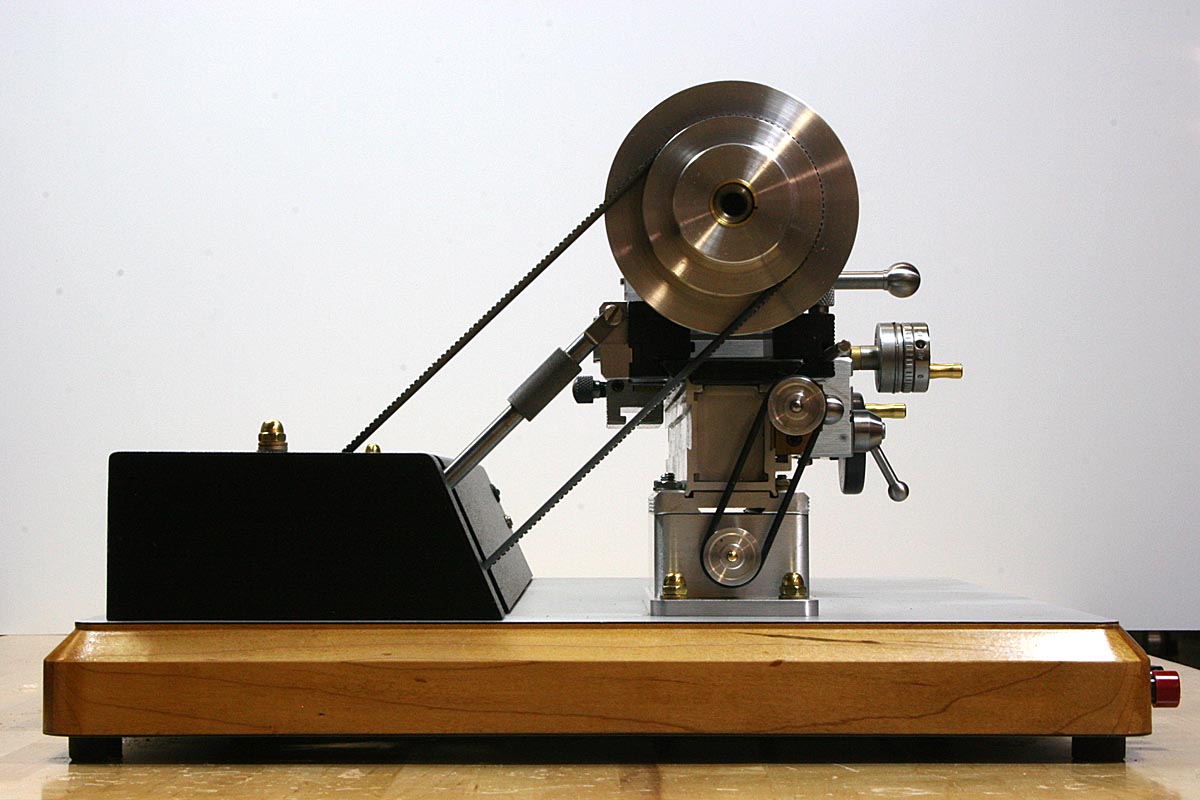

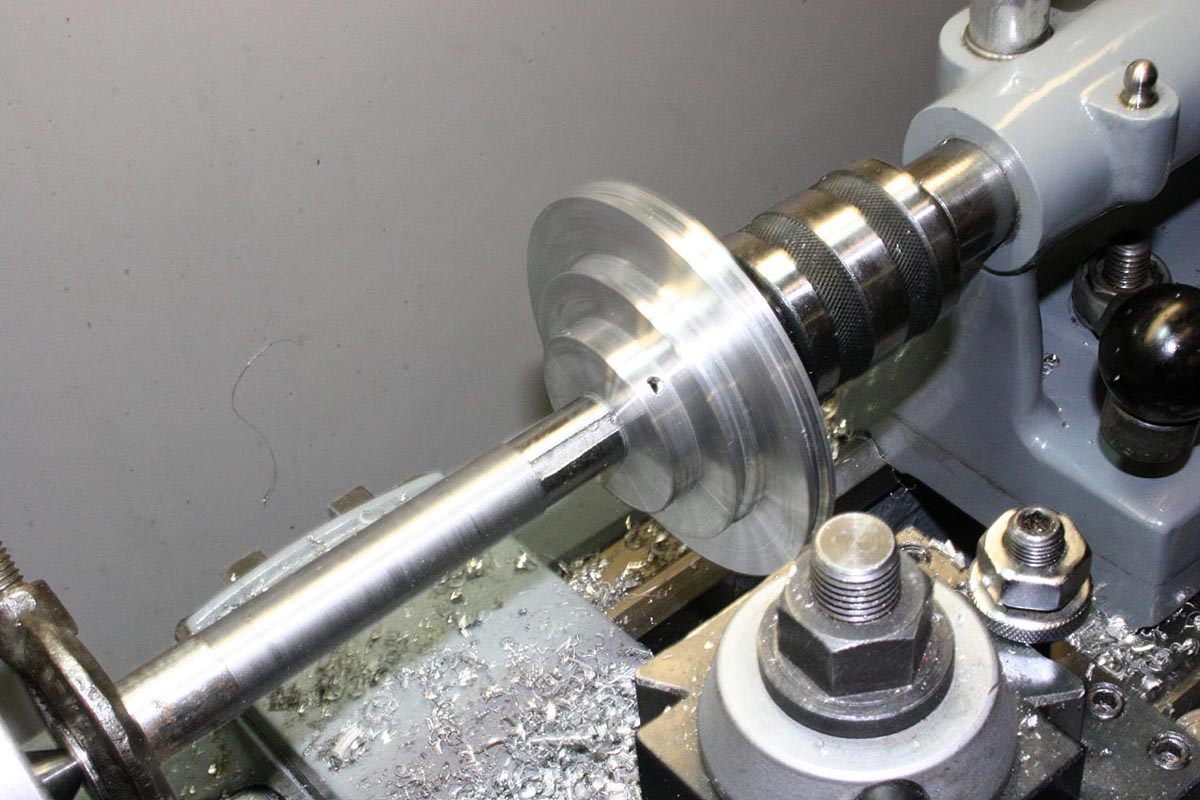

- Roughing Out the Headstock Pulley

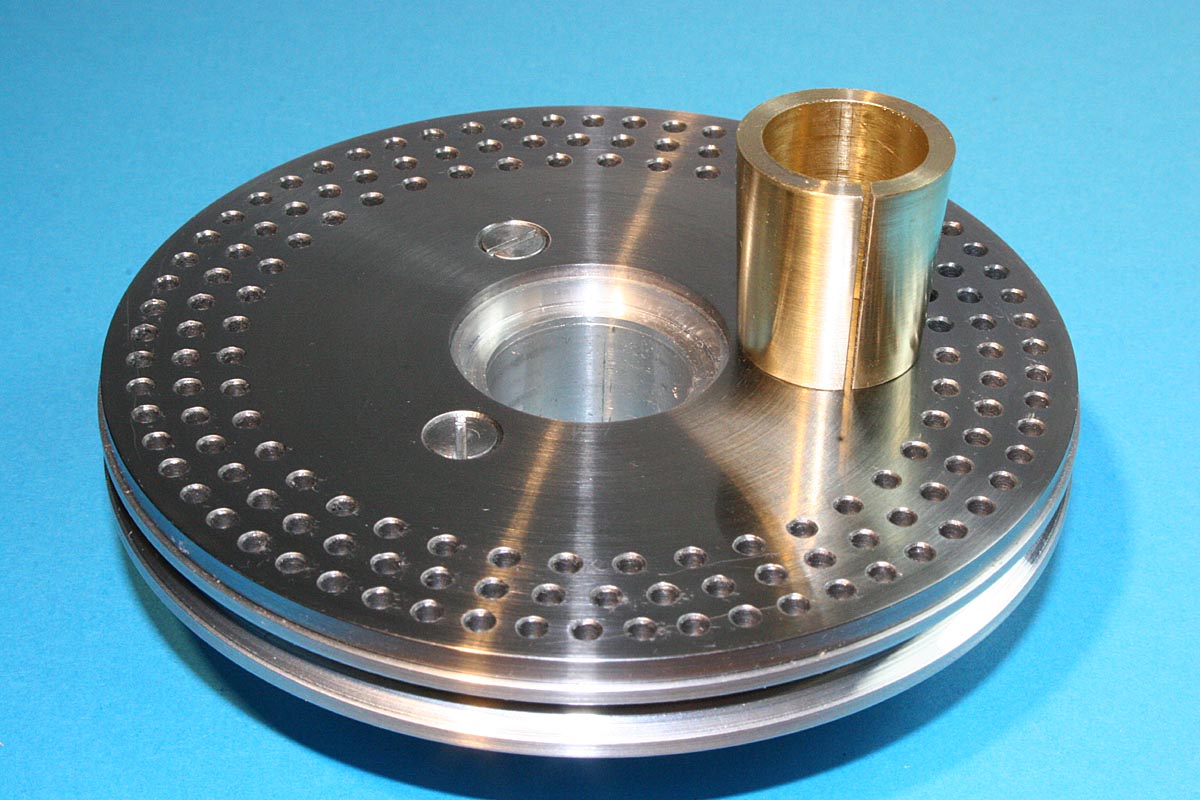

- Headstock Pulley with Tapered Bushing

- Eccentric Bearing Bored Out and Fitted With Acetal Inserts

- Rear Switch / Circuit Breaker and Power Entry

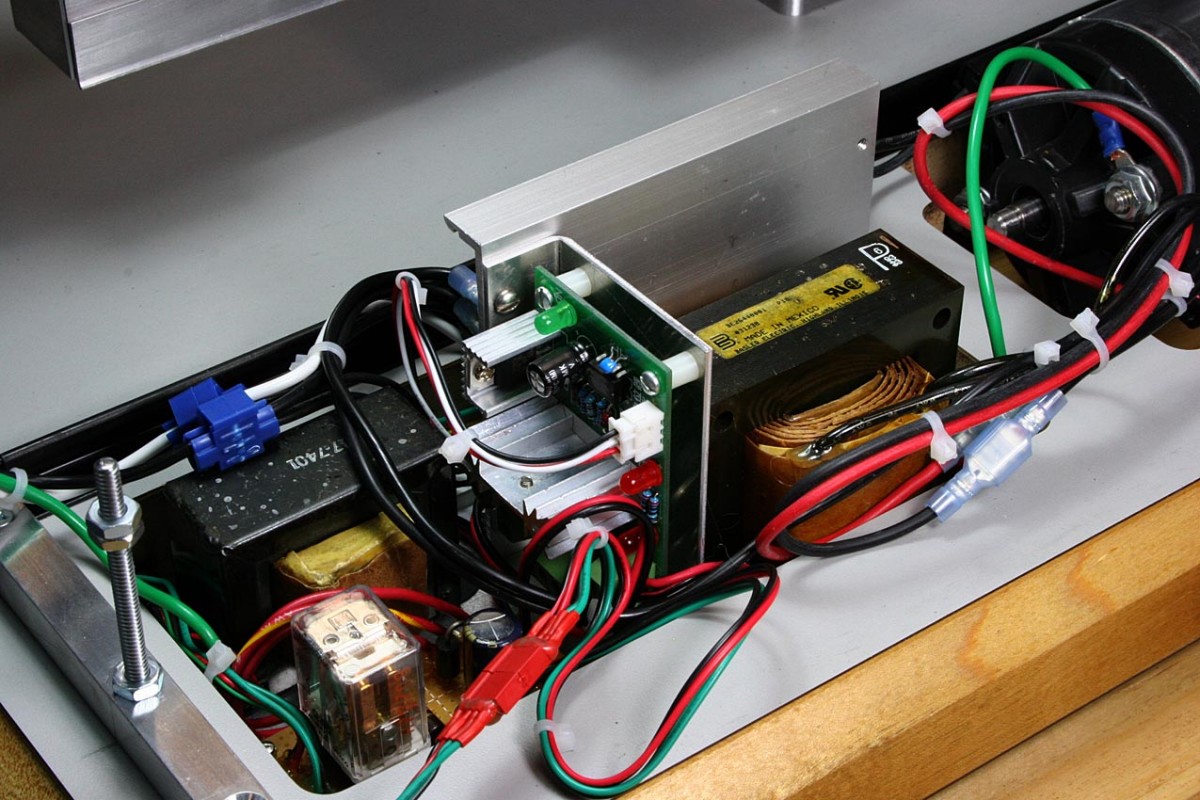

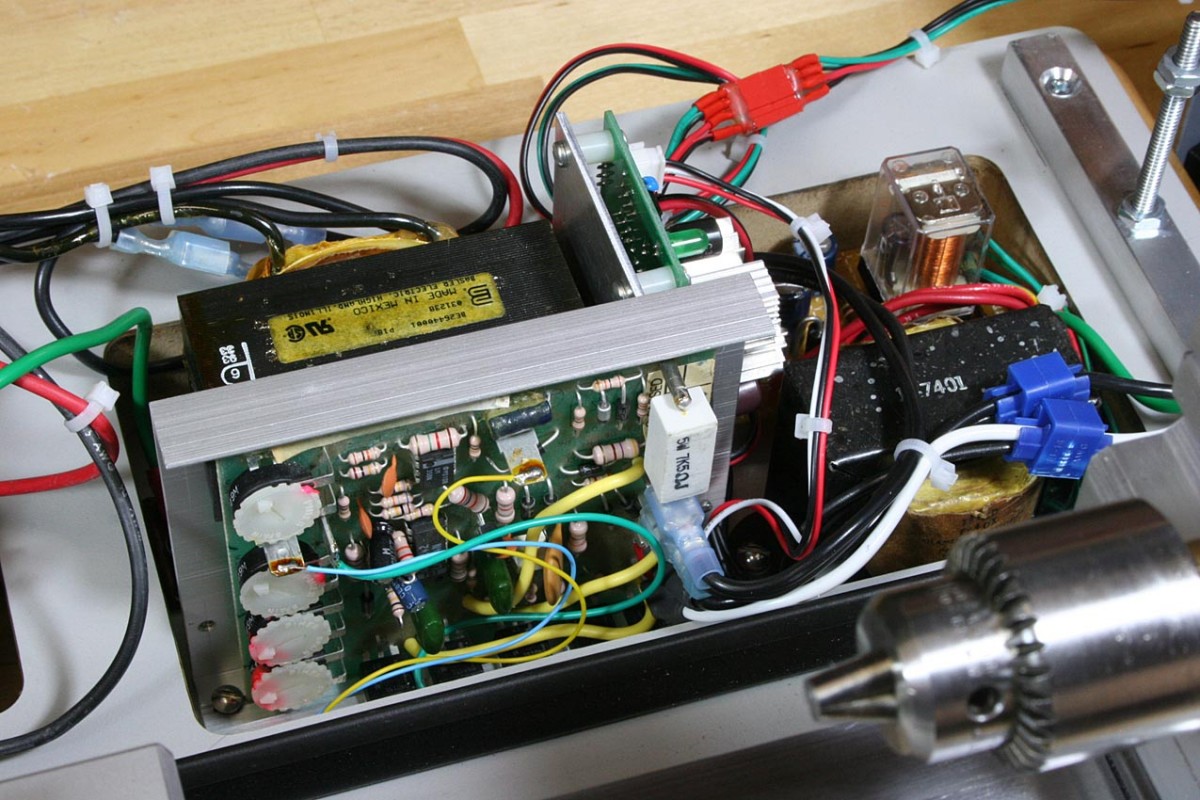

- Electronics For Spindle and Feed Motors – Rear View

- Motor Electronics – Front View