The Workshop

-

-

Front-to-Back:

Welding Bench & Storage, Mill-Drill, Lathe, Sculpting & Soldering Bench, Sheet Metal Brake and Shear

-

-

Facing Main Workbenches and Paint Carousel Rack

-

-

Sculpting & Soldering Bench Under Window. The Tiki Watching Through the Window Was Made as a Youth Over 45 Years Ago

-

-

Welding Bench and My Trusty Rong-Fu Mill-Drill, Nearly 30 Years Old

-

-

Another View of the Workbench Cluster

-

-

Walkout is Handy for the Big Things.

-

-

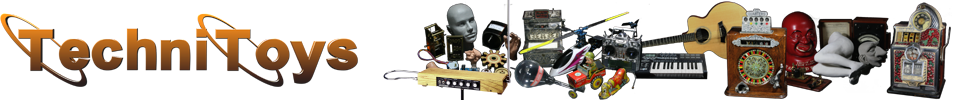

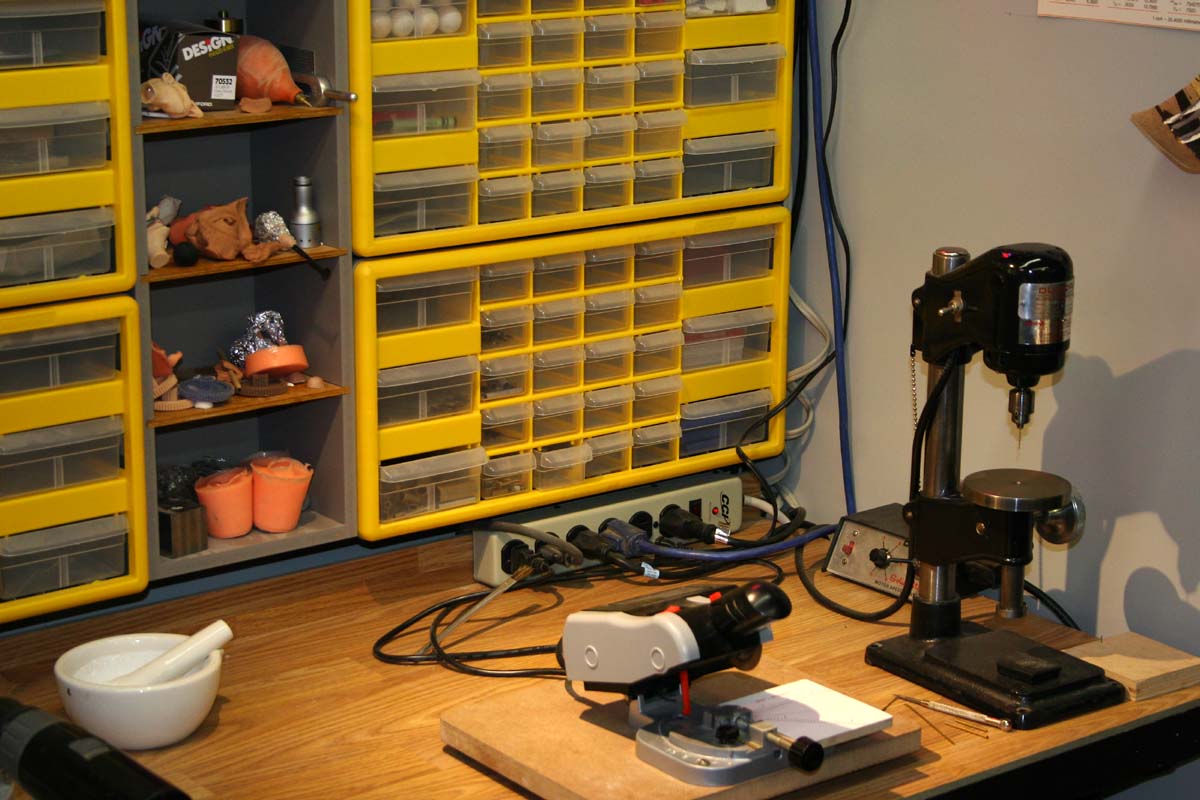

Cannot Have Too Much Storage Space

-

-

Modified Harbor Freight Cutoff Saw Used For Small Brass and Wood & Dumore Sensitive Drill Press

-

-

The Taig Micro Lathe is Often on this Bench Beside the Dumore

-

-

Homemade Carousel Tucked in Unused Space

-

-

Wax Sculpting Tools and Small Metal Stock Storage

-

-

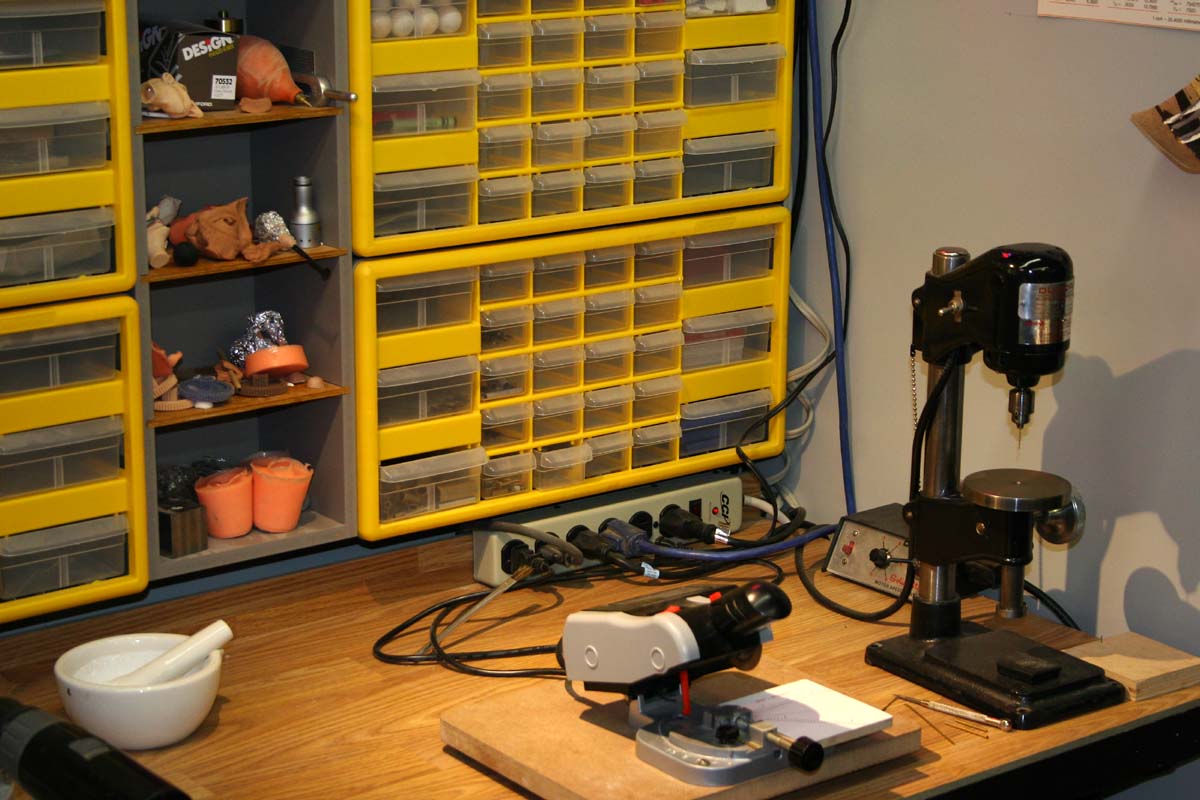

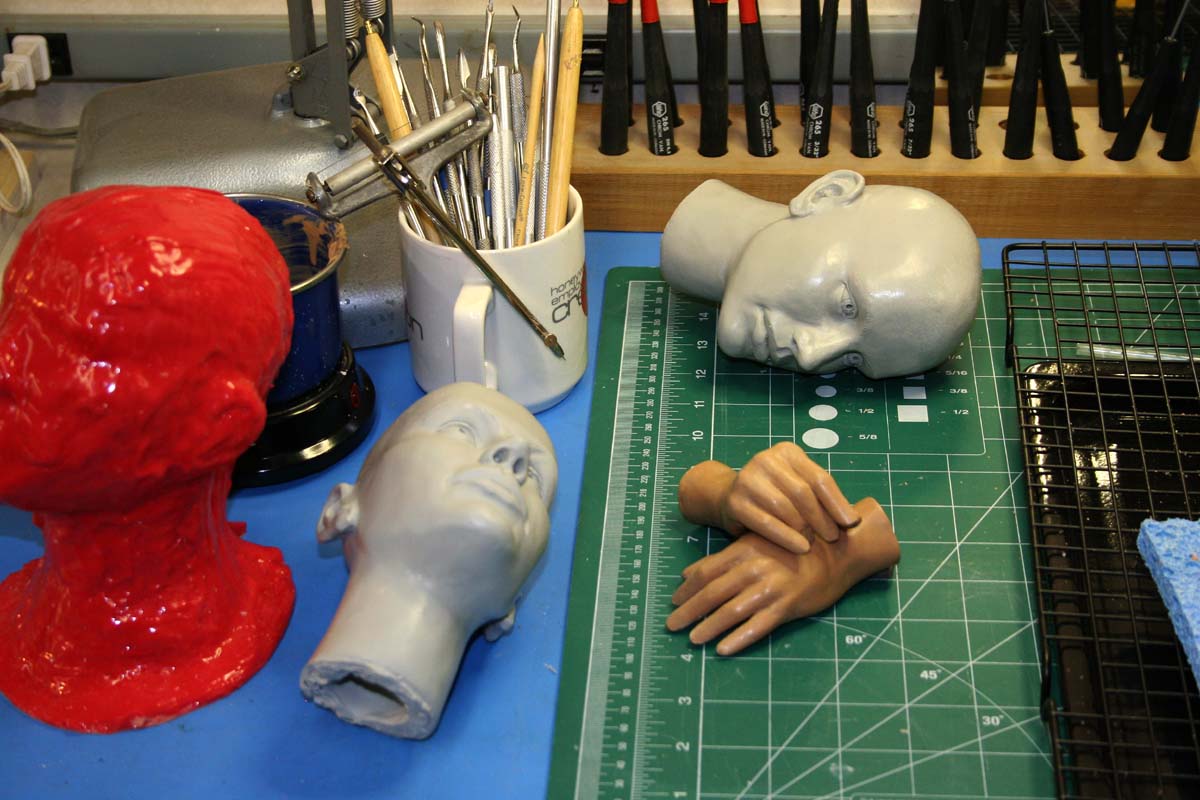

Wax Automaton Heads & Hands in Progress

-

-

Pre-Warmed Wax in a Cup Spoons Faster Than Cold Wax

-

-

An Oven Grate on Top of a Pan Keeps Sticky Wax Chips Away From Working Surface. A Brass Brush Head Mounted to Grate Keeps Tools Clean

-

-

An Automaton Wire Frame Being Fitted With Mockup Hands

-

-

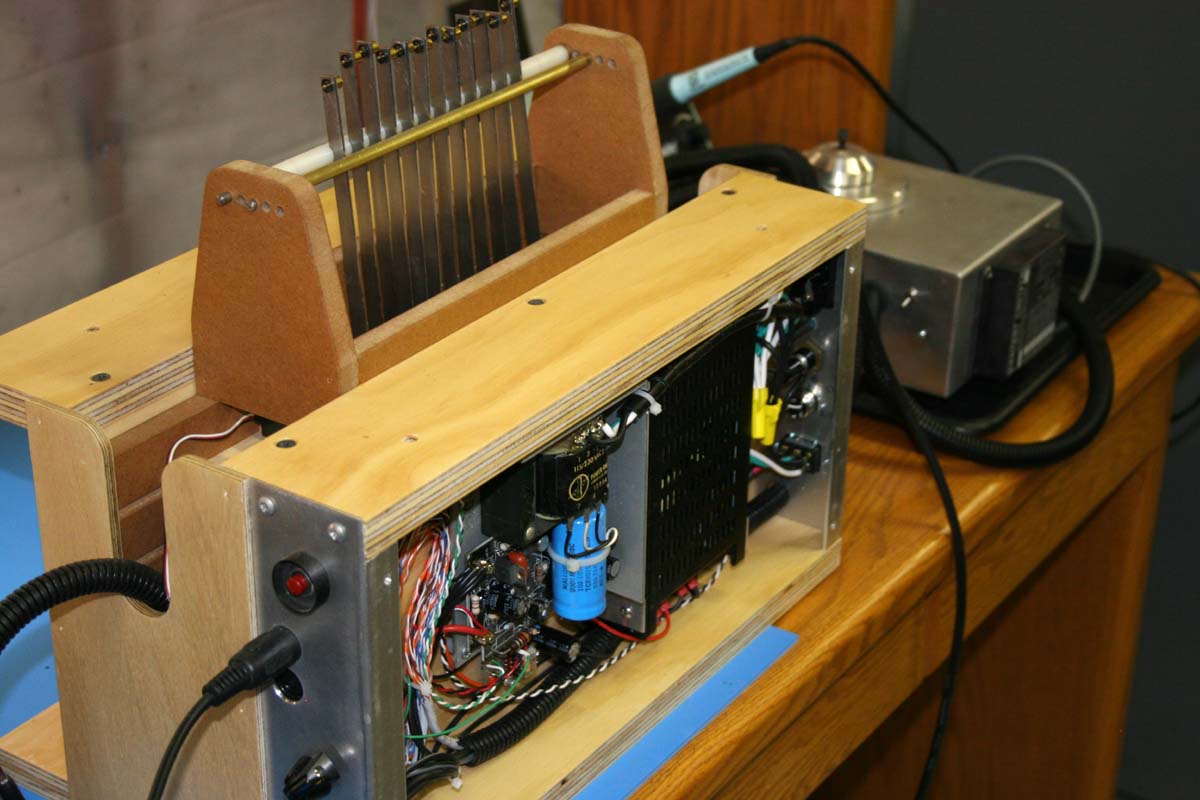

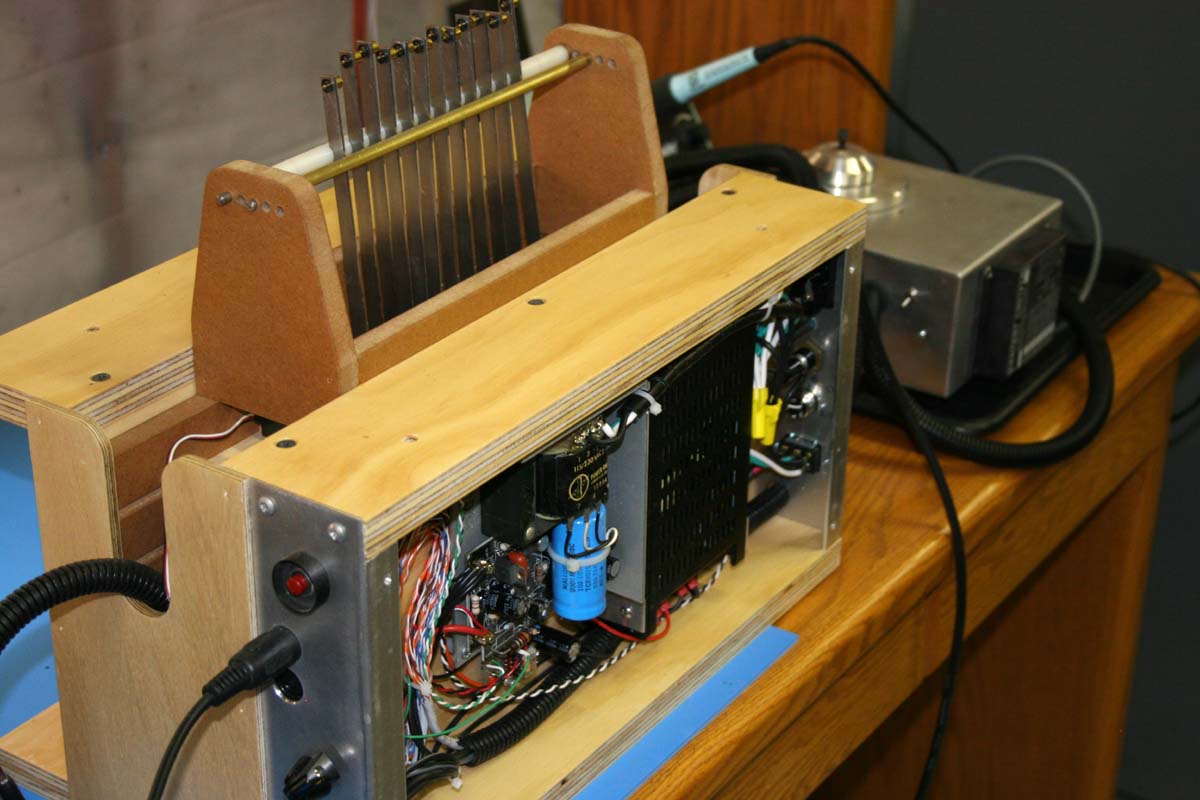

Homemade Resistance Soldering Unit – See Article

-

-

Custom-Made Universal Swivel for Neck Joint

-

-

Well Used Mill-Drill, Still in Good Shape

-

-

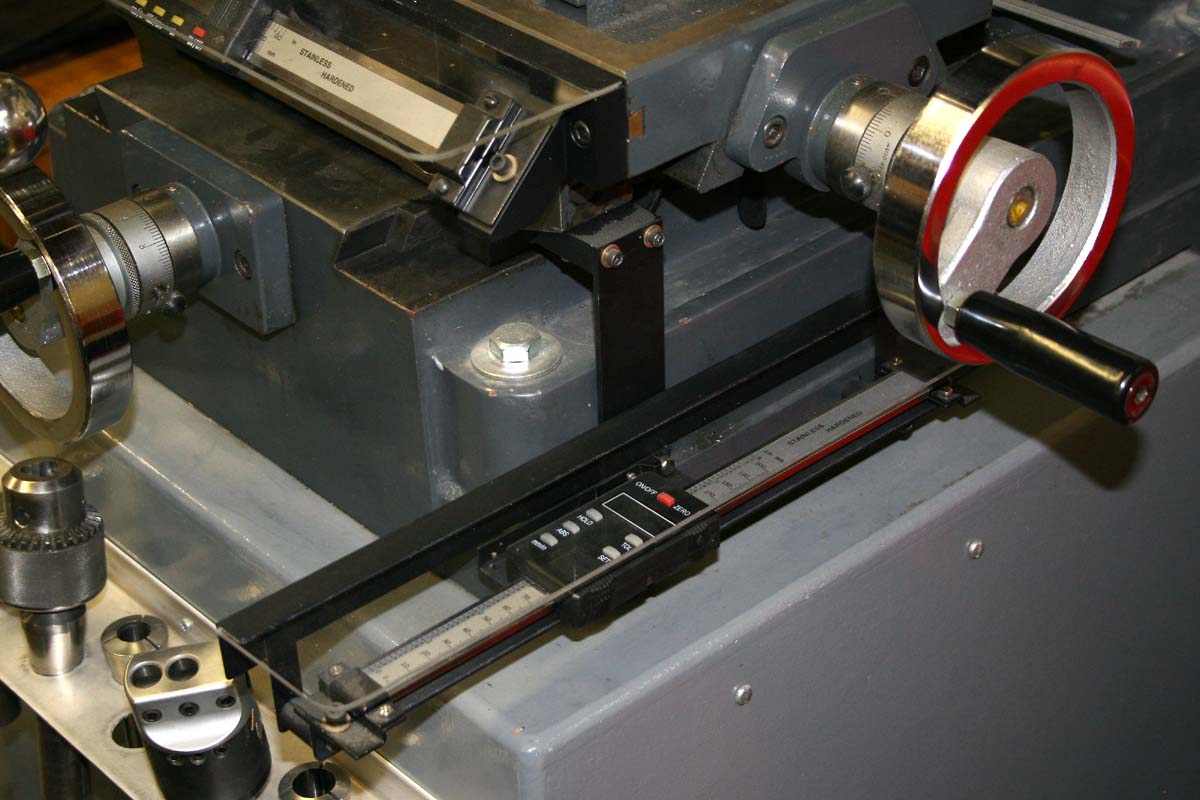

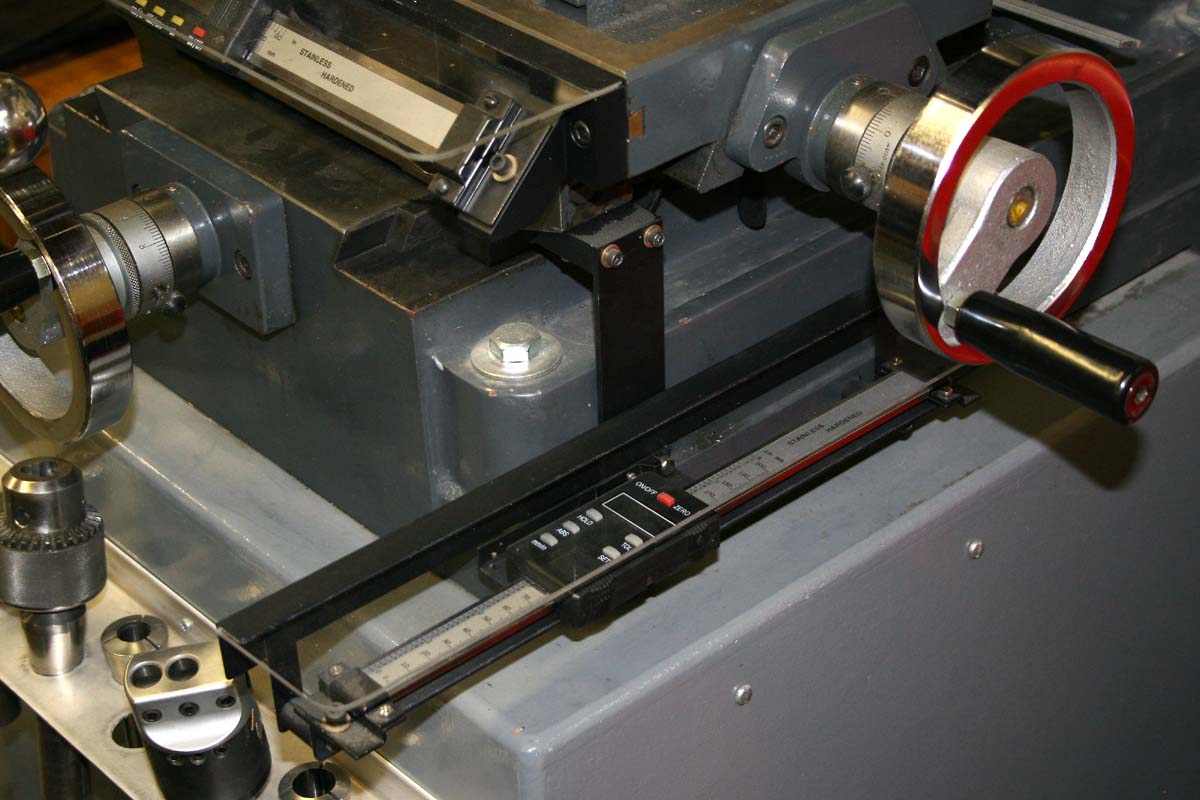

Milling Machine Z-Axis Digital Scale

-

-

X-Axis Digital Scale Under Acrylic Chip Guard

-

-

Y-Axis Digital Scale Also Under Window

-

-

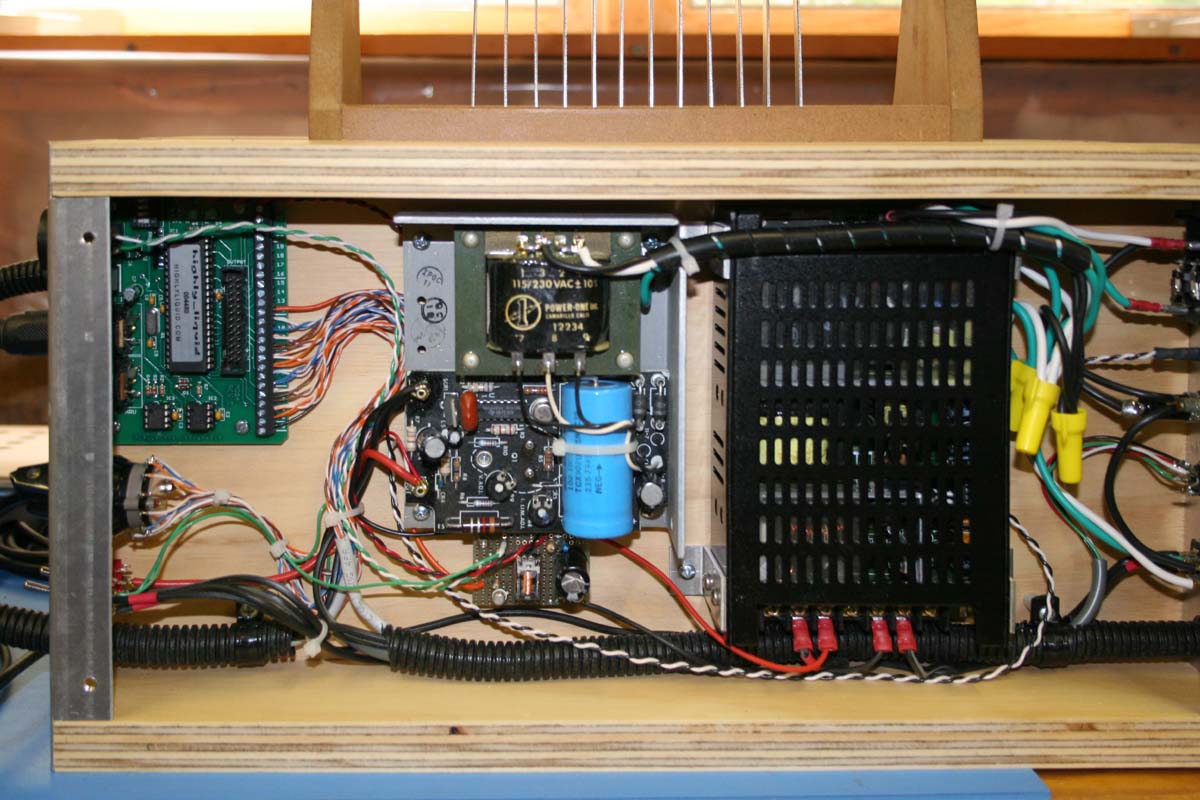

Automatatron – Servos Choreograph Automaton Movements Via Computer & MIDI, Then it Cuts Cams One at a Time to Mechanically Replicate the Servo Movements

-

-

BCF-2000 MIDI Control Surface and Automatatron – Part of Setup to Record Automaton Movements and Cut Brass Cams

-

-

This Mounts on Mill Table and Moves Under Computer Control for Cutting Cams

-

-

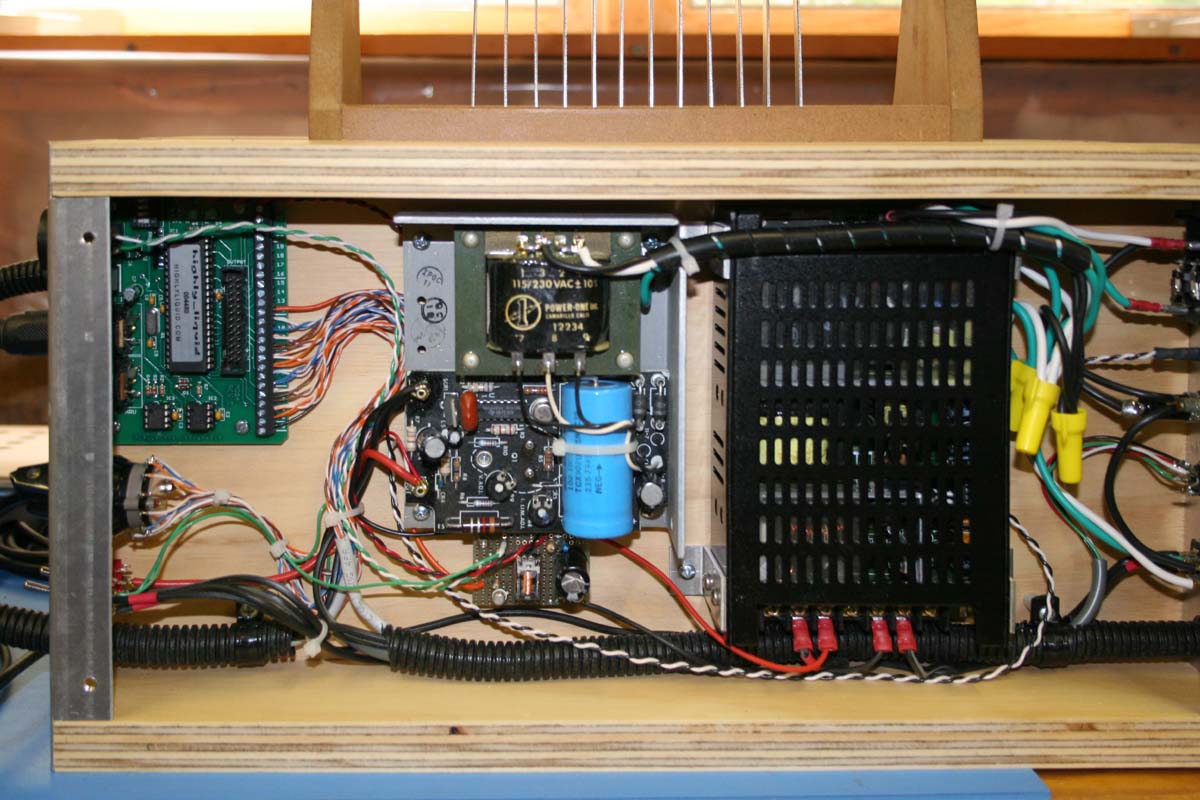

Inside the Automatatron – MIDI-to-Servo Interface and Power Supplies

-

-

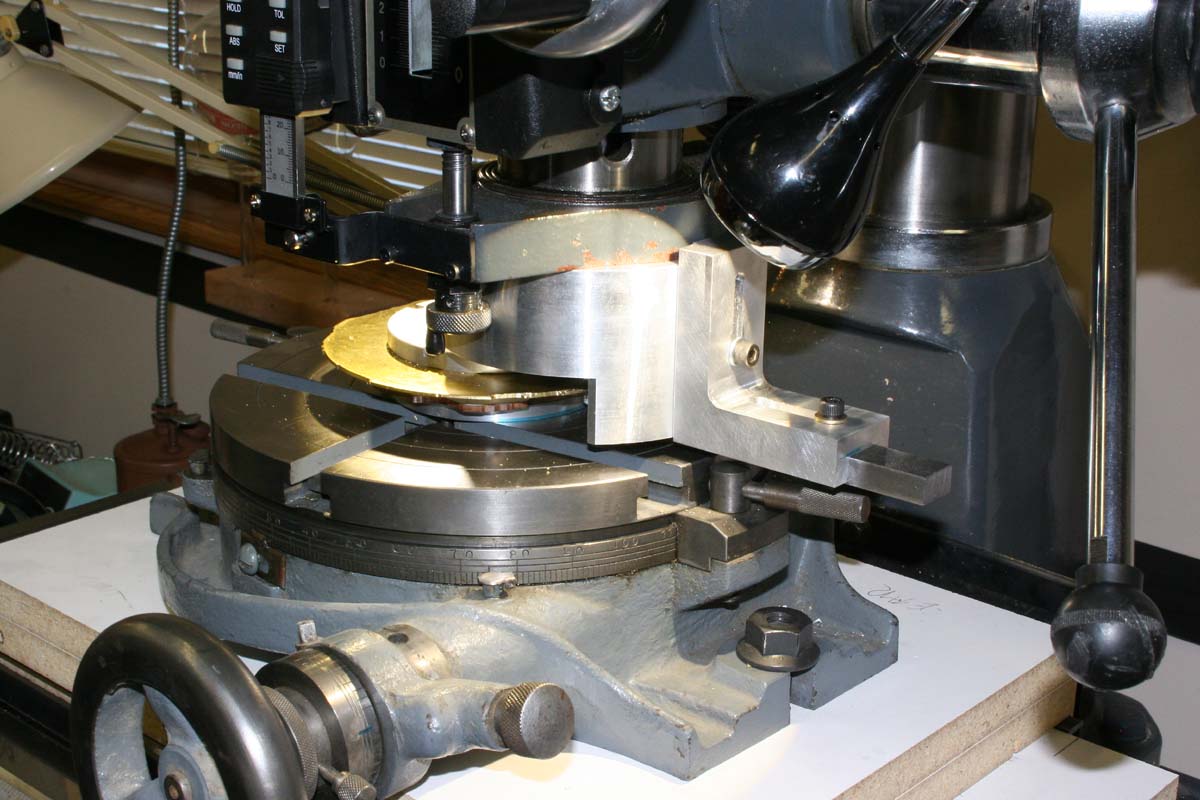

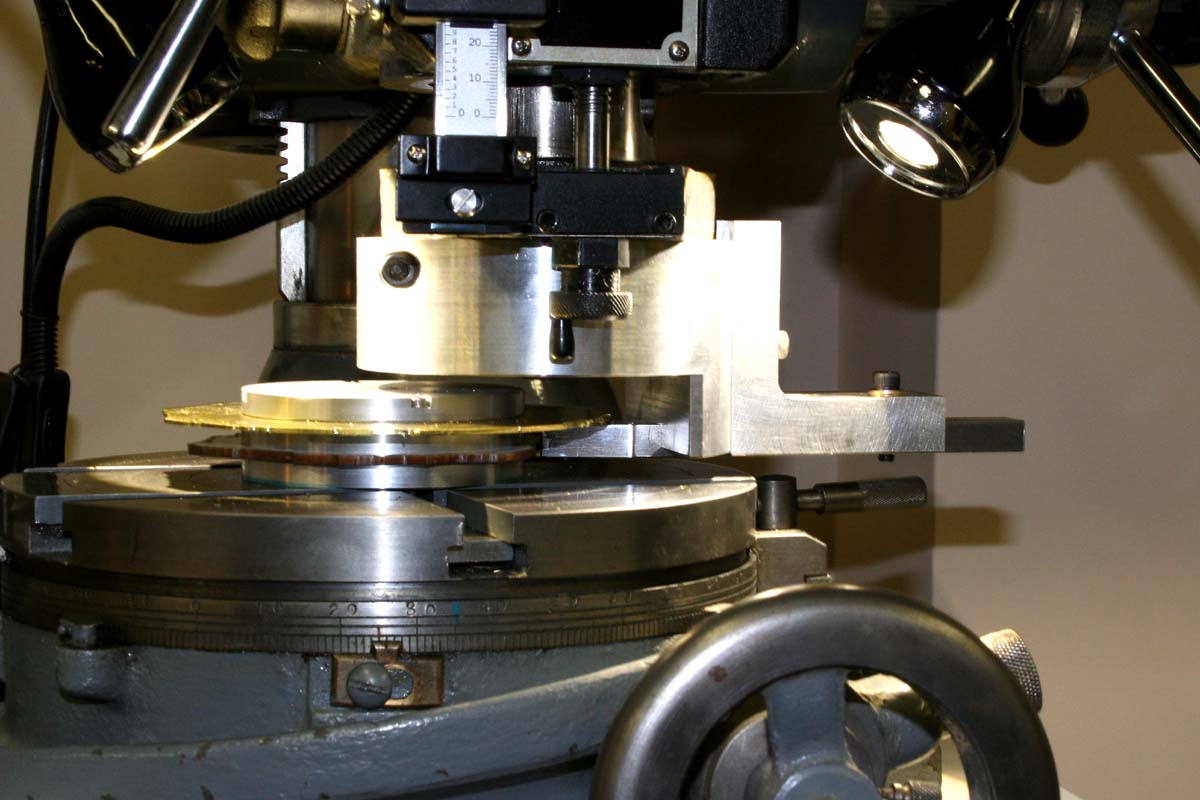

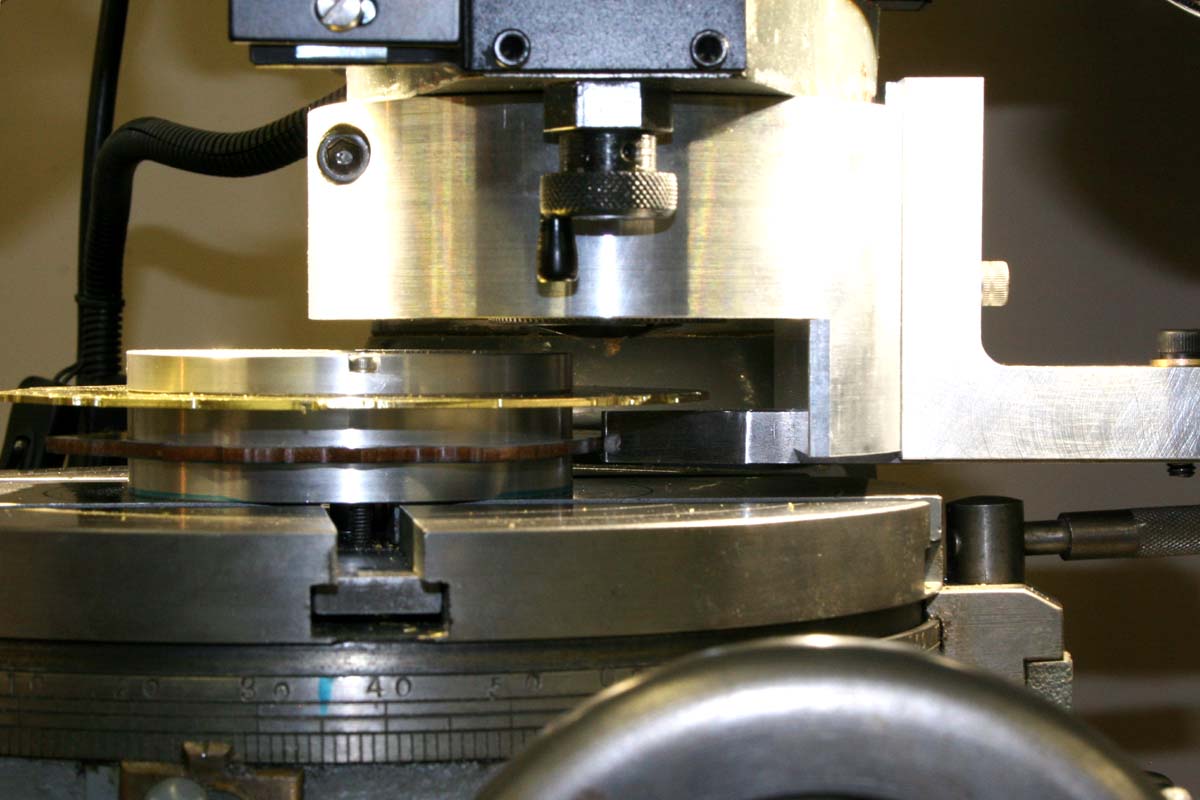

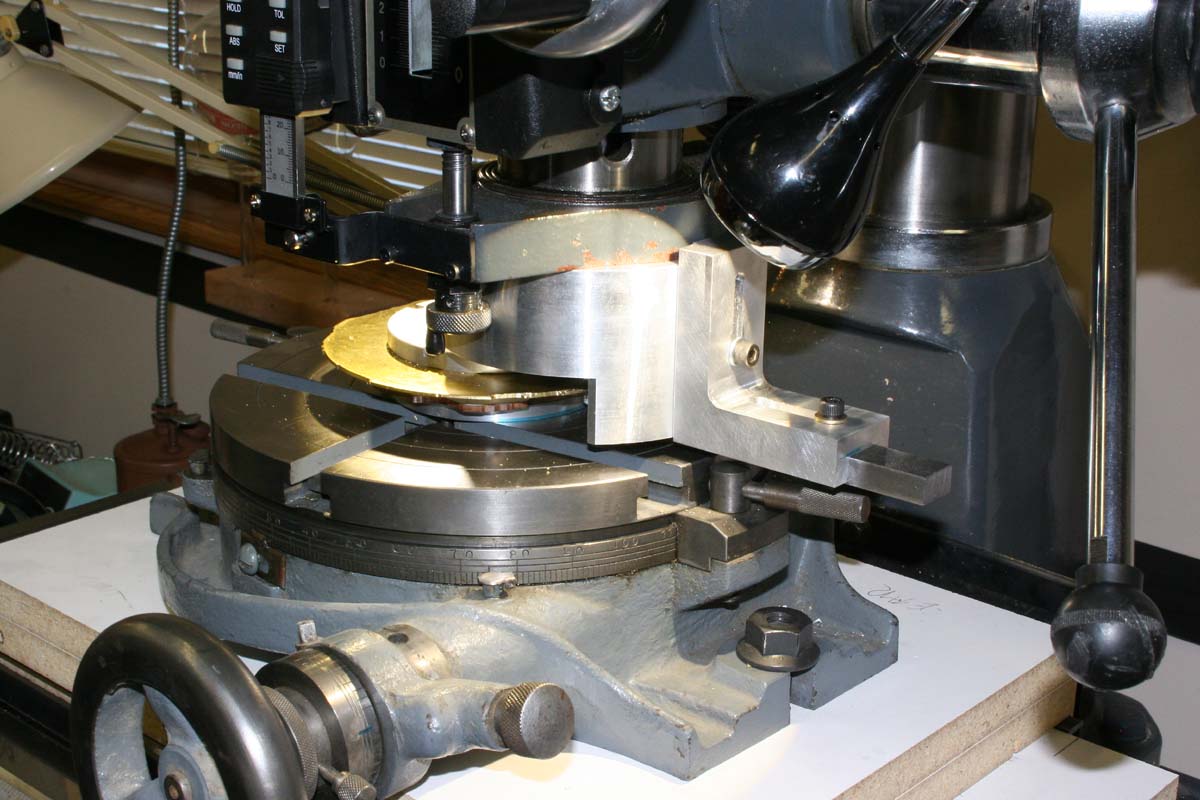

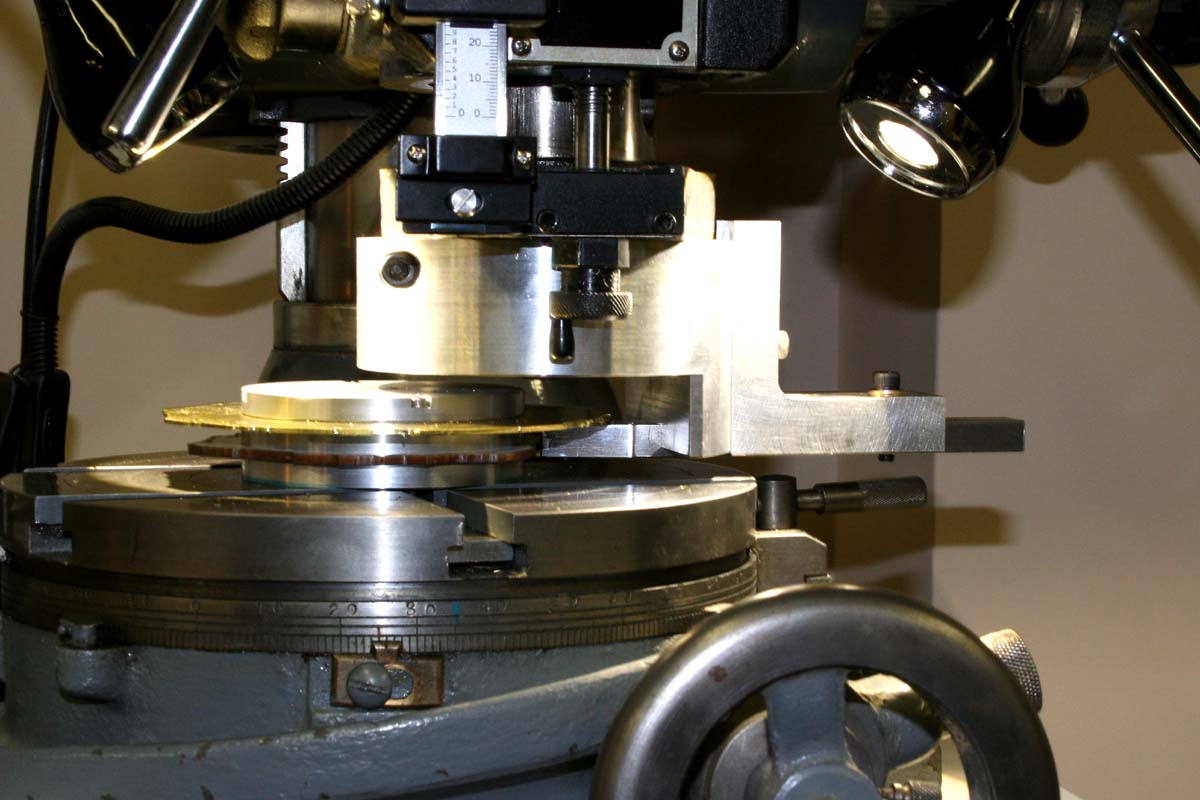

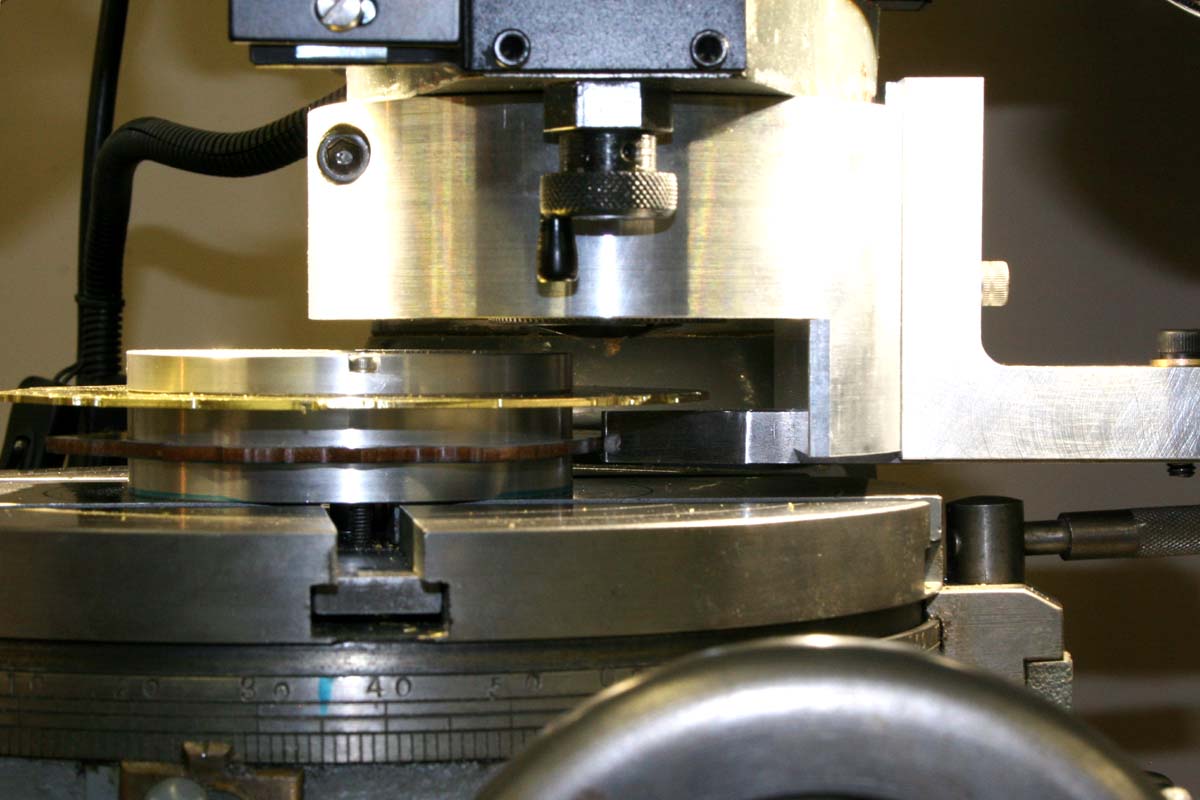

Brass Cam Disk Being Copied From Hardboard Original

-

-

Brass Disk is Larger Than Hardboard Original

-

-

Follower on Right Center Rides on Hardboard Cam – Rotary Table is Free to Slide Left to Right

-

-

There is No Milling Cutter in the Collet – This is Early in the Setup

-

-

My Trusty Logan/Wards 10″ Lathe, Recently Restored After Nearly 30 Years Together

-

-

The Lathe is Powered by a Variable Frequency Drive and a 3 Phase Motor – the Belt is Routed Vertically into the Cabinet Below

-

-

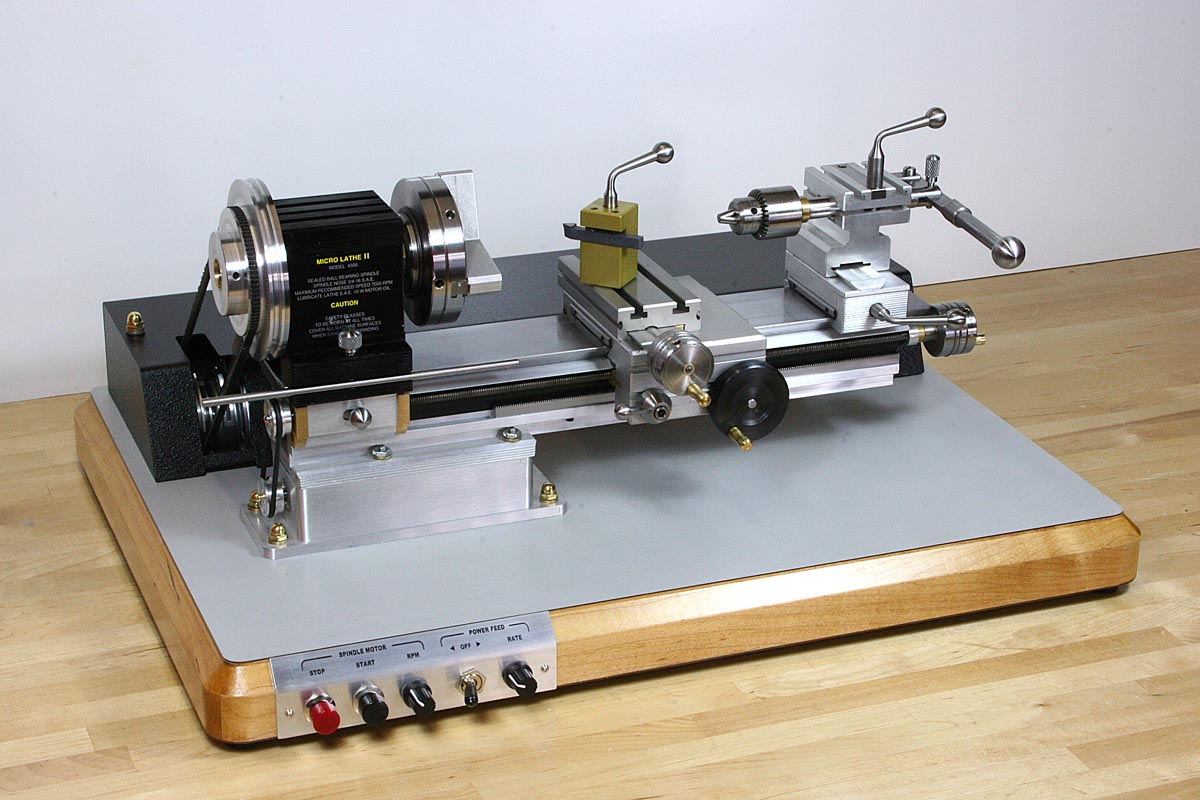

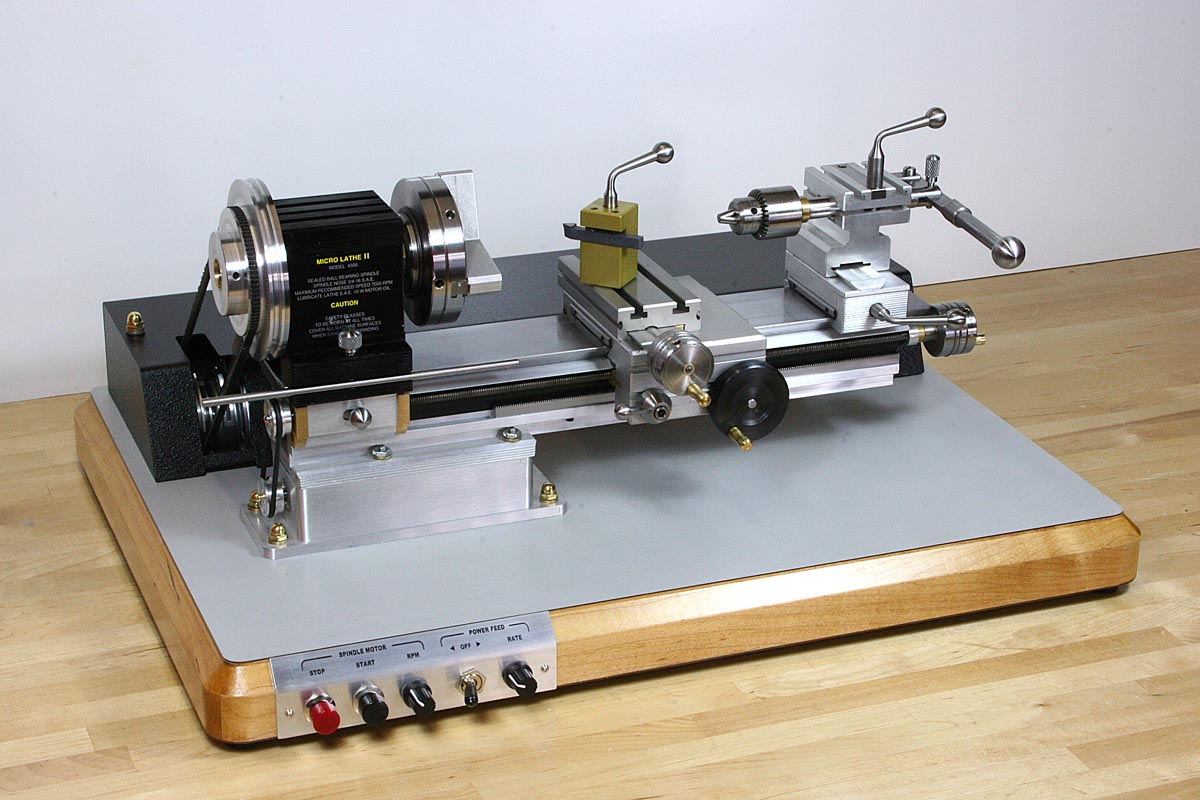

Customized Taig Micro Lathe II for Smaller High Speed Work

-

-

The Microscope Aids Fine Work and Lets You See How Bad You Are at Bit Sharpening

-

-

Storage for Everything Short, Plus Some Trade Stimulators on Top Awaiting Restoration

-

-

Lathe Tooling Opposite the Lathe. A Nice Mills War Eagle on Top is Also in Line for Restoration

-

-

Watching in 3D

-

-

Table Saw, Scroll Saw, Thickness Planer

-

-

Sheet Metal Brakes and Shear; Clamp Storage

-

-

Downdraft Dust Filtration & Outfeed Table In Foreground

-

-

Second Bandsaw, Spindle Sander, Belt Sander

-

-

Main Bandsaw and Disk/Belt Sander

-

-

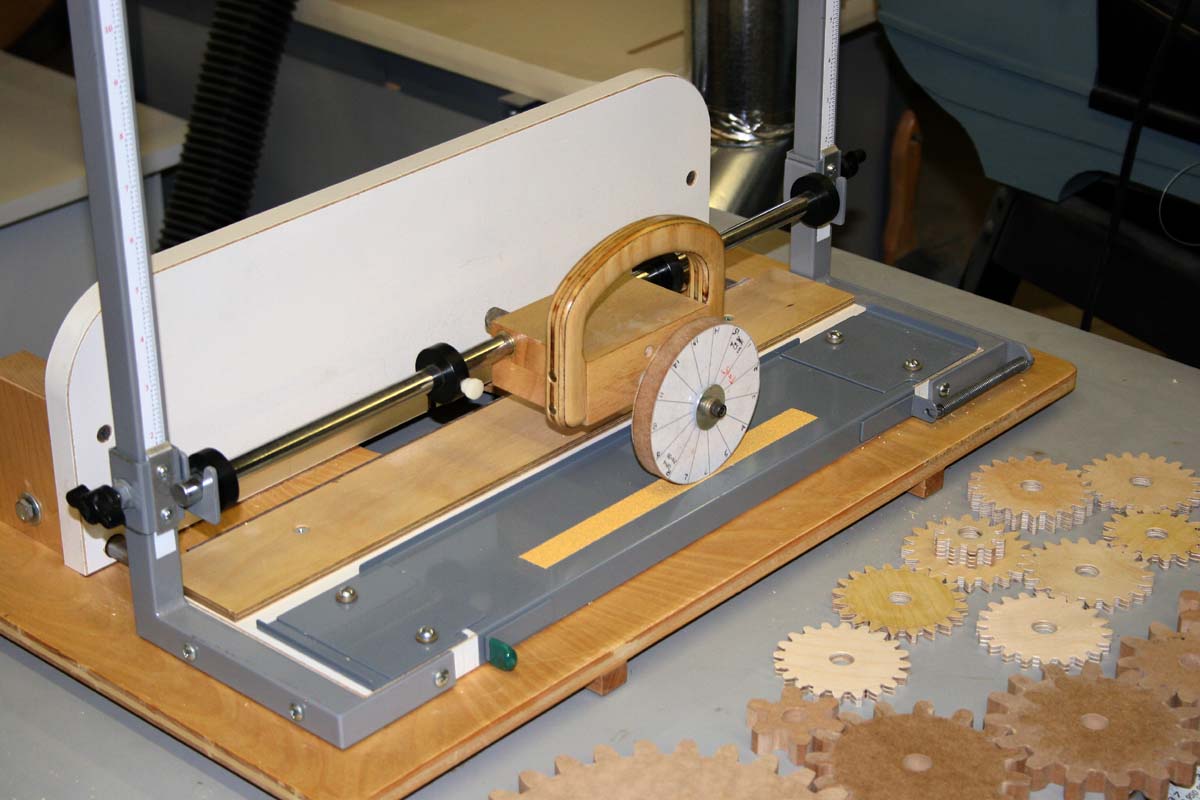

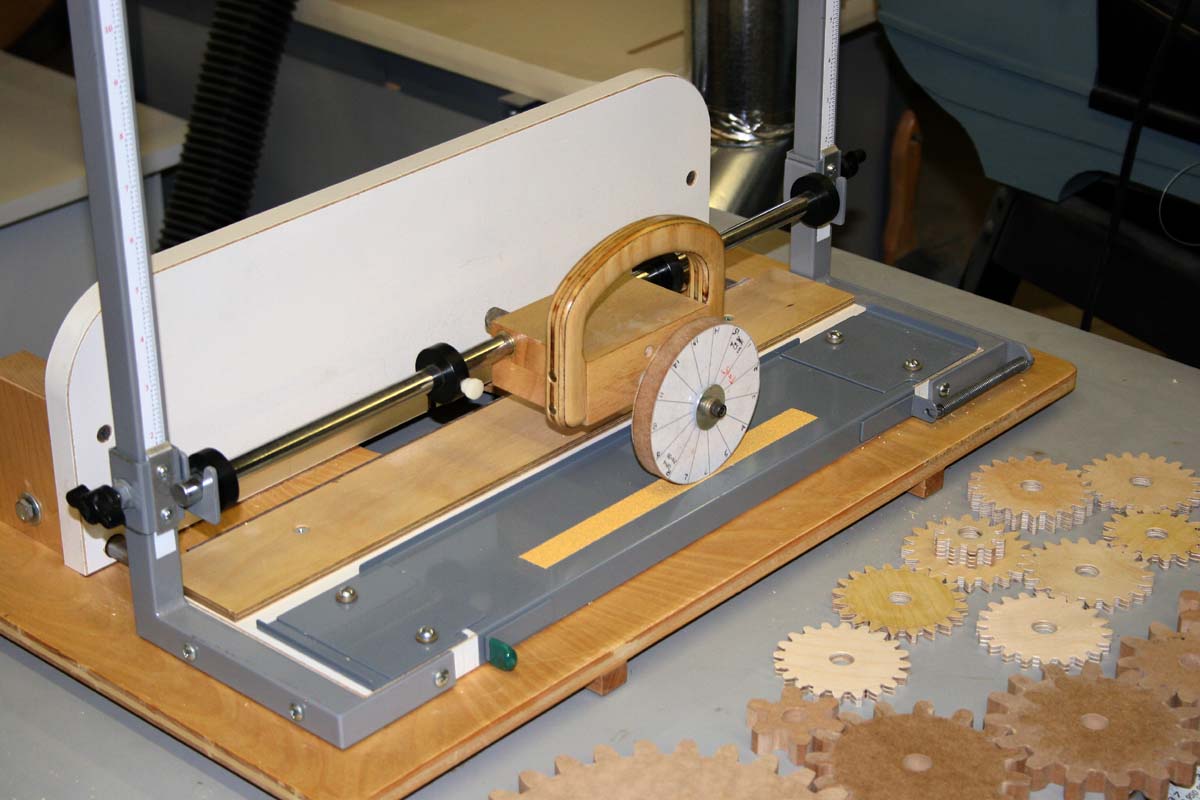

My Gear-Cutting Jig For the Table Saw Shown With Some Sample Gears

-

-

This Will Be the Subject of an Upcoming Article

-

-

Precision Table For Sanding Disks for Gear Cutter

-

-

The Table Swings at the Right End

-

-

And This Knob Sets the Stop Depth for Easing Up to Exactly the Correct Diameter

-

-

This is a Dust Collector, Outfeed Table for the Saw, and a Power Tool Storage Rack

-

-

Blower Output Passes Through Grill on the Bottom

-

-

Tool Storage in Otherwise Wasted Space in Dust Filtration Table

-

-

Inside the Dust Bench. A Furnace Blower is Housed in the Center with Furnace Filters on Either Side

-

-

Metal Storage Rack on Casters – It’s Still Hard to Move

![]()