Edge-Lit TVs Are Like a Box of Chocolates…

Displaying LCD Technology in the Worst Possible Light

I would guess that LCD TV enthusiasts, owners, and potential buyers that lean more toward the videophile/home-theater end of the spectrum represent a fairly small percentage of the overall market. If you are part of this minority and follow discussions on AV forums dedicated to such topics, you will learn about quality control issues that plague just about every make and model of flat-panel TV on the market. In some cases you will learn about flaws that you may never have noticed on your own, and once they are seen they usually can’t be unseen. But it is better to be able to spot a problem immediately within a return or warranty period than to suddenly discover it on your own when it is too late. Being informed can assist you in making a better choice in selecting a TV; it can also cause frustration to find out that no matter what make or model you choose, luck almost always plays a role.

It is pure speculation on my part, but it seems plausible that the Edge-Backlit LCD TV business model has settled on this general quality control philosophy:

If it lights up and displays a picture, ship it. Quality control acceptance or rejection will be provided by the customer.

LCD TVs, once scorned by those who care about things like black blacks and color uniformity, have made substantial improvements in a very short time. These improvements are partly due to improved panel processes, and also partly due to clever backlight dimming techniques that help offset some of the inherent shortcomings in the LCD panel itself.

But instead let’s talk about the stupid backlighting trends that in many cases are hobbling these advancements.

Note: While it is common to use the term “panel” to refer to the entire assembly of the LCD array and the layers and components associated with backlighting, I will at times be referring only to the active liquid crystal panel.

HDTV and monitor LCD panel technologies and signal processing have advanced dramatically in just the past couple of years. 70″ to 80″screens are found lining dealer’s walls and aisles, and gone are the laggy, low contrast, narrow viewing angle displays that marked the beginning of the flat screen era.

Unfortunately some of these technological advances have been stunted by the trend of using a system of edge-lights and a sandwich of thin film layers to provide the distributed backlight for the LCD panels.

Early flat screen TVs and computer monitors used a parallel array of thin CCFL (cold-cathode fluorescent) tube lamps spaced behind a translucent diffuser. Banding of the backlight was minimized by optimizing the quality of the diffuser, minimizing the spacing between adjacent lamps, and providing adequate distance between the diffuser and the lamps. CCFL backlit TVs could not be very thin, and were usually several inches thick depending on the screen size. While reasonably efficient, CCFLs, much like hot-cathode fluorescent lights, have a limited life and require the use of high voltage switching power supplies.

LED backlighting if implemented properly is a natural fit for LCD panel lighting. LEDs are a more energy-efficient light source and generally have an extremely long life, although the active driver circuits that provide a constant current to the LEDs can fail before the LEDs themselves. LEDs can also be dimmed easily (unlike CCFLs) and some more advanced TVs will allow the backlights in dark areas of the image to be intelligently dimmed, enhancing the black level beyond the darkening capability of the LCD panel alone. More on this later.

The natural progression for transitioning to LED backlighting of LCD panels involved replacing the tubular CCFL lamps with distributed arrays of point-source LEDs. This is known as full array backlighting. As in the case of CCFL lighting, uniformity was a function of the spacing between adjacent LEDs and the spacing of the LED array from the diffuser panels. This need to keep the LEDs some distance away from the diffuser panel prevents the full-array TV from getting as thin as an edge-lit design.

Ignoring any variations in the LCD panels themselves, which is a separate issue, the uniformity of full array backlighting is quite consistent. Any deficiencies in light uniformity (which I have never really seen) using full-array LED backlights would be seen as hot-spotting rather than banding as is the case with CCFL tube lamps. But with this type of design the expectation would be that if you did see any backlighting-related deficiencies on the display model at Best Buy, you would probably see the same deficiencies on the next one in the stack or one purchased at a CostCo 2000 miles away. This is a consistent lighting method – one whose uniformity depends on the design, not production variations, and not luck-of-the-draw.

Full-array backlighting also allows groups of LEDs, allocated into zones, to be dynamically dimmed under black areas of the screen, and the full-array can handle dimming scenarios that no other form of backlighting can handle (a white screen with a black center, for example).

Unfortunately, TVs with full array backlighting have almost disappeared from the market in favor of the more economical edge-lit design.

At some point, thin became sexy. Bezels became narrower and panels grew larger and in some cases became ridiculously thin. It should also be noted that regardless of the apparent thinness of the panel edge, other electronics and connectors that can’t be contained within that thin form factor contribute to the need for the hump or pod that is present on the back of all of the thin sets.

But whatever is driving the trend toward LED edge-lighting with ultra-thin panels – cost reduction, marketing studies, who knows what- it certainly isn’t picture quality. It is also a fair question to ask how much the drive toward thin packages has compromised the designs of support electronics and cooling. Perhaps this is a contributor to the perception that you should not expect your lovely new HDTV to last more than a few years, or sometimes much less than that.

The fundamental problem of poor uniformity with LED edge-lighting is not in any way the fault of the LEDs; they are merely the light source, and a good one at that. The real problem lies in the technology of the light distribution panel, and more specifically in the sensitivity of that technology to manufacturing and material inconsistencies. Flashlighting, Clouding, DSE (Dirty Screen Effect), Banding, Non Uniformity, and Backlight Bleed are all terms used to describe the flaws present in far too many (dare I say the majority?) of edge-lit LCD TVs right out of the box.

Speaking not as a lighting expert but as a frustrated consumer who happens to also be an engineer, here’s an unsolicited opinion: manufacturers really might want to think about getting a handle on this lighting problem before trying to sell us on the virtues of 4K versus 2K resolution, or before adding more slick marketing features when you haven’t fixed those that didn’t work on your last model. Like certain models of smart phones that do nearly everything except excel as a telephone, could we talk manufacturers into trying to produce a TV that doesn’t suck as a TV before trying to turn it a streaming social multi-media lifestyle whatever?

Read the AV forums and you will see that there are potential buyers that are tracking which panels are getting used in which TVs (by serial number) in an attempt to “find a good one”. Some owners with blotchy screens are rubbing them with microfiber cloth in an attempt to massage out some lighting anomalies, with varying degrees of success. And others are loosening the screws on the perimeter of the screen, because they have found that minor variations in panel stresses caused by a different screw torquing sequences can sometimes help.

This all points to one thing, and you don’t need to be a backlight panel expert to understand it: the sensitivity of edge-lit panel uniformity to manufacturing and material variations – over which manufacturers clearly have inadequate control- is too high. An example case describing the astounding out-of-the-box differences between two identical TVs will be given later.

How Edge Lighting Works

An inside look at the construction of the light distribution layers of an edge-lit TV is fascinating in its hidden complexity, and yet it’s disheartening when you to see how a fundamentally compromised design can get signed off and in effect contribute to an entire industry trending toward a lowest common denominator product that customers will still tolerate.

The light distribution layers of edge-lit panels can vary somewhat, but a key element is the panel that reflects incoming light from the edge-mounted LEDs at a right angle toward the viewer. This is a thin, flexible panel sometimes called a light guide. All of this reflection occurs due to very many small ridges contained within the thickness of the light guide, like many thousands of small mirrors all carefully aimed to catch any light coupled to the guide’s edges and aim it directly at you. The ridges have to be graded in height so that the ridges near the center, those farthest away from the edge light source, receive their fair share of light to reflect and are not obscured by the ridges closer to the edge.

Once the light is successfully diverted toward the viewer so that the has a uniform brightness over the entire area, additional layers of film place in front of the light guide can be tailored to spread the light to provide a wider viewing angle or to compensate for other non-uniformities.

It is this stackup of thin, flexible film layers, including the active LCD panel, that appears to be highly variable. Anyone who has ever pushed a finger into an LCD laptop screen knows how sensitive it is to stresses and distortion.

The sandwich of flexible films that comprise the edge-light distribution system cannot be squeezed into flat submission in a 10 ton platen press; it’s more like trying to flatten the lettuce in your sandwich by pinching only the crusts together. The protective glass screen front is flexible. The active LCD panel is flexible. The back of the whole panel is flexible. And they are all trying to contain and flatten the inner films that, on a macro scale, appear very compliant, but on a more micro scale have wrinkles, bows, and waves. These deviations from perfect flatness all require some degree of pressure to overpower – pressure that is difficult to apply in the center of a large screen when the outer faces that apply the pressure can themselves flex and bow.

It is also no wonder that some of the techniques that owners are using to try to improve their screens do, in some cases, have an effect . With a full black signal input (0%), and with the backlight fully on, a common flaw called clouding will show up as lighter patches on the dark background. It takes very little pressure on the screen – often no more than you would use to clean it – to be able to chase the clouds around like bubbles in a water bed (if you remember water beds!). Sometimes they change permanently; more often they stay the same or just move a little. The active LCD panel itself could be a contributor; it is difficult to identify the real source of the problem without risking the TV, but it seems to be generally accepted that the worst problems are correlated directly to edge-lit designs.

A Tale of Two TVs

A few years ago I decided that TV manufacturers had worked out enough of the problems that it was time to try one. We brought home what I guess would be considered at the time a mid-tier Samsung model. Unfortunately with that one purchase I was able to learn both about dead pixels and this flaw known as clouding. Back to the store it went – clustered dead pixels are a less arguable cause for rejection than clouding, but the clouding was in fact worse than I would have believed it could be.

Through chance and fate, and a truly helpful sales person, I was steered to a sister store that had a few Sony KDL55HX800 models. I bought one, and it was very, very good. The panel blacks were good to start with, but it also had dynamic edge lighting which actively turns off the LEDs in regions that are black, enhancing the contrast. The LED dimming was so effective and so well implemented that we bought a second identical set a few days later for use in another room. Unfortunately, the second set was not up to the standard of the first. There was a vertical, faintly dark band visible on blue green backgrounds that I noticed right away. I didn’t like it, but I would live with it if it did not get worse.

Well, it took a while, but it got worse. I waited until near the end of the warranty and submitted pictures to Sony; they concurred that the panel was defective and needed to be replaced. Arrangements were made, a repair visit was scheduled, and then I got a call. Their message: We have no panels, they are not economical to replace anyway, and your HX800 is therefore considered unrepairable (still in warranty!). But We would like to offer you one of our lovely reconditioned current R550A models as a replacement.

My Reply: Sorry, but no thank you. An R550 is in no way an equivalent replacement for an HX800, and you know it.

Thankfully the seller stepped up and gave a full refund of the initial purchase price. Even that was not a happy ending, because I really wanted that particular model, but it simply was not available anywhere.

But those weren’t the two TVs of this tale.

After doing some more research, I semi-reluctantly decided to try a 70″ passive 3D TV by made by a top name manufacturer. There had been some issues with this particular model, but it did have some terminology implying an LED dimming feature emblazoned on the box, and that feature had become of utmost importance at this point. By now I had learned that the best way to compensate for lousy backlight and panel uniformity is to turn off backlights before your eyes can adapt to a dark screen. Of course the panel still had to be reasonably good at the darkest gray levels when the light has to be on.

TV “A”

I picked out a lucky one, brought it home and set it up in a dark room with the backlight level at minimum. I loaded a test disk with gray fields, and went to 0%, full black. There was some flashlighting, but I wasn’t worried about that for now. There was some clouding with full black, but the acid test for me is whether you see it during film credits. Usually even credits put enough white on the screen that your pupils constrict to the point that light clouding is not a problem. And with the LED dimming feature, full black – where the clouding would normally be most obnoxious – is presumably accompanied by LED shutdown, and hence total blackness. I could live with this, even though I couldn’t figure out how to get the dimming to work in a useful way.

With the correct settings I was eventually able to get the LED backlights to shut off when transitioning from 1% near black to 0% black, but it would only happen about 6 or 7 seconds after the transition to full black. This told me that LED dimming functionality was there, but the delay, which I did not understand and could not disable, rendered it useless. The LEDs are supposed to transition to off almost simultaneously as the LCD goes full dark. After trying virtually every setting that should make this happen, but with no success, I called the manufacturer.

After working through the obligatory first-level support questions, I started getting transferred laterally through and then up the support chain. After nearly two hours on the phone and a wait for a call back, I talked to someone who finally understood my description, and evaluated the TV as defective. A new set was offered, but I indicated that it would be simpler to return it to the store in a few days and get a replacement.

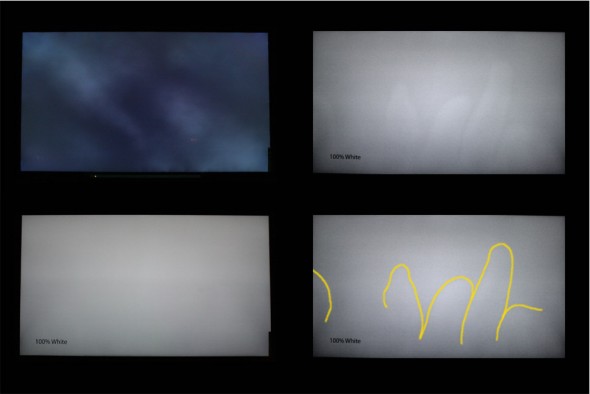

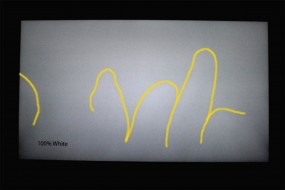

With nothing else to do for the rest of the day I started checking out the picture and features running on some program material, and a few minutes in something started to jump out, although it was hard to define what it was. The screen had a faint pattern that was visible on skies and panning images. So the test disk went back in and the pattern was set to 100% full white. That’s when I was introduced to DSE, short for the appropriately-named Dirty Screen Effect. Imagine that the TV had been strapped to the top of your car following a Diesel truck. After a few thousand miles you stop at a gas station and give the screen a few half-hearted swipes with a windshield rag. That is exactly what it looked like.

Note: If you are viewing this on a device with an improperly calibrated display , you won’t see this effect. Enlarge and toggle between the two images.

Photos can never capture the full effect. It was quite awesome in its badness – it looked like it was giving me the finger. I still don’t know what causes this, but it was quite immune to anything I tried, and there was now no doubt that this TV was going back.

TV “B”

I had to go to a different store to buy the replacement, actually before I returned the first one. They were disappearing from stock quickly, and they were going inactive it this particular store, so I had to move quickly.

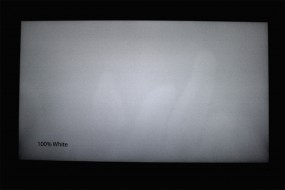

Got it home, same room, same setup… except this time I started with the 100% white test. The white looked great, like it should.

The next stop was the black level test, and I sort of expected it to look a little better too. Not so. It was much worse than the first set.

To be fair I should point out that the dark picture on the right is taken with an automatic exposure on the camera, and the clouds are not as bright as the picture would indicate. However, it is a true indication of the relative variations that you seen in a dark room. The background leakage glow is there, as is every feature of the clouding. This was a show stopper, and not surprisingly it failed the movie credit test miserably as well.

And at this point it came as no great surprise when I proceeded to test the backlight dimming feature and found it to behave exactly the same as the first set – the LEDs would go black 6 to 7 seconds after a full black input signal was applied. This behavior made the dimming feature useless for its intended purpose, and the manufacturer had agreed that this was not the correct behavior.

Now I had two sets identical by name and model but with both common and individual flaws. One set had to be returned, and the other needed either multiple repairs or to be returned as well. It wasn’t even clear which set was better – both had serious flaws.

First Things First – Fix the LED Dimming Problem

I contacted the manufacturer again and started all over at the bottom of the support chain, again spending a few hours reaching the right people. Although I had in the past been able to escalate an issue with this particular company (on a different product) to the point of having a conversation with an engineer in a cubicle somewhere (who admitted to a design anomaly), that was not to be the case this time. The best that could happen was that the issue would be handed off to Engineering for evaluation, but at least there was one contact liaison that I would be working through.

Support attempted to duplicate the problem while I was on the phone, but it turned out they did not have the correct model set available. When questions came up on how exactly to duplicate the test, it became very telling about what their capabilities were, and they did not even have the capability of providing test patterns that were needed. I sent links on where they could obtain the test pattern files, and left them to do what they could do. I really did not expect to hear from them again.

A few days later I received a follow-up call from the support liaison. At the time it was funny in that he sounded nervous or excited, and perhaps a little practiced on how he was going to say what he had to say. Engineering had been contacted and my results had been duplicated in their lab, on their test set. And the kicker? They had identified the LED dimming behavior as a design flaw and they had no immediate solution for it, but they would be looking into it. He also thanked me profusely for bringing it to their attention. Admissions like this are surprising when you hear them, but they have happened before, and that may be a good topic for a future article.

I do give them credit for doing the work and admitting to the problem, but how could I possibly be the first person to have noticed this? Maybe others have, and perhaps this is one of those things that falls off the manufacturer’s radar as soon as your TV is deemed obsolete. If a manufacturer can lose interest in supporting a TV while it is still in warranty, as was the case with the HX800, it may not be much of a stretch to expect lackluster support to clean up rarely reported problems, even on current models.

And the Panel Defects?

Unfortunately, I never even got to the point of discussing those with the manufacturer. If the dimming feature problem had been solvable, there would be the possibility of still finding that model of set that might have a good panel. A verified hardware or firmware problem with dimming on an unknown number (or all) sets ruled that out. In the end, discussing panel quality issues with support would probably have ended in no real satisfaction anyway.

In the End

In more than two months I have not heard of any follow-up on the dimming problem (they offered to keep me informed to satisfy my own curiosity) but after returning both sets I washed my hands of any of the problems associated with this make and model TV. The downside is that between the wasted time spent on performing field QA and the risk of getting blacklisted for returning defective TVs, purchasing another TV is currently off the table. The immediate goals are to keep the HX800 running and wait for OLED TVs to become mainstream.

![]()